Abstract

Groundskeepers may have increased risk to noise-induced hearing loss due to the performance of excessively noisy tasks. This study assessed the exposure of groundskeepers to noise in multiple universities and determined the association between noise exposure and variables (ie, university, month, tool used). Personal noise exposures were monitored during the work shift using noise dosimetry. A sound level meter was used to measure the maximum sound pressure levels from groundskeeping equipment. The mean Occupational Safety and Health Administration (OSHA) and National Institute for Occupational Safety and Health (NIOSH) time-weighted average (TWA) noise exposures were 83.0 ± 9.6 and 88.0 ± 6.7 dBA, respectively. About 52% of the OSHA TWAs and 77% of the NIOSH TWAs exceeded 85 dBA. Riding mower use was associated with high TWA noise exposures and with having OSHA TWAs exceeding 85 and 90 dBA. The maximum sound pressure levels of equipment and tools measured ranged from 76 to 109 dBA, 82% of which were >85 dBA. These findings support that groundskeepers have excessive noise exposures, which may be effectively reduced through careful scheduling of the use of noisy equipment/tools.

Keywords: groundskeepers, noise exposure, noise dosimetry, exposure assessment, public universities, occupational noise

Introduction

Approximately 870,000 groundskeeping and landscaping workers are employed in the United States. Based on the 2014 data, North Carolina (NC) employed 28,900 of these workers, ranking it as the eighth state with the greatest number of employment in this particular work sector.1 Workers in this occupation perform various tasks, including mowing, trimming, sod laying, raking, planting, and installing concrete landscape structures (eg, patios, pathways) and irrigation systems.1,2 Power equipment and tools are used to a great extent in many of these tasks.

Noise is an important occupational hazard in various occupations, including the groundskeeping sector. The U.S. Occupational Safety and Health Administration (OSHA) estimates that about 30 million U.S. workers are exposed each year to excessive noise at work. Consequently, noise-induced hearing loss (NIHL) has been one of the most common occupational diseases in the past 25 years.3 According to the National Institute for Occupational Safety and Health (NIOSH), worker compensation costs due to NIHL in the United States were estimated at $242 million each year.4 An estimated 16% of adult hearing loss worldwide is attributed to occupational noise exposure.5 In 2013, the Bureau of Labor Statistics reported that nearly 11% of all nonfatal, work-related diseases are NIHL cases.6

Studies related to the workplace exposure of groundskeepers to noise are limited. A study comparing NIHL between landscapers and carpenters was previously conducted,7 but their noise exposures were not evaluated. The operation of groundskeeping/landscaping equipment (eg, riding and push lawn mowers, chippers, shredders, stump grinders, chainsaws, edgers, leaf blowers) without using hearing protection equipment has been identified to contribute to NIHL.8 Limited documents addressing worker health and safety in the landscaping industries are available but mainly focus on the safety hazards and prevention of injuries from operating-related equipment and tools.8,9 Noise exposures of certain occupations, such as construction,10–13 agriculture,14–17 and forestry,18,19 have been studied more extensively in the published literature, and may be similar to those of groundskeepers because of the similarity in some of their tasks and tools. Additional information is beneficial in further understanding the noise exposures of groundskeepers and the contributing factors and may be used to tailor strategies for noise exposure reduction specifically for groundskeepers. In a recent pilot study, which is the only published study to our knowledge on such work group on noise exposure, groundskeepers employed in a university were found to be excessively exposed to noise.20 The purpose of this study was to expand on the pilot study by assessing the occupational noise exposure of groundskeepers employed in three public universities in NC, and by evaluating the association between noise exposure and certain variables, such as university, month, and tool used, as these may contribute to differences in the groundskeepers’ noise exposures. Month as a variable may assess the seasonality of noise exposures; different universities may have different landscaping features that may affect the type of tasks performed by workers, and have different policies affecting worker noise exposures; and certain equipment and tools may be more associated with higher noise exposures than others due to the noise they produce and the duration of time they are used.

Methods

Participant recruitment

Full-time groundskeepers employed at three public universities (UnivA, UnivB, and UnivC) in NC were recruited to participate in the study. Approval to conduct the study was obtained from the East Carolina University Institutional Review Board. During recruitment, groundskeepers were provided information about the study, and were informed that they can choose not to participate without being penalized. Informed consent was obtained prior to the conduct of noise monitoring. Personal identifiers from data collected in this study were removed (ie, de-identified) prior to data analysis to eliminate the linkage between participants and their corresponding data.

Noise dosimetry

Monitoring for personal noise exposure of groundskeepers using noise dosimeters has been previously described.20 Each noise-monitoring exercise covered the full work shift (typically 8–10 hours). Noise dosimetry was conducted for 45 monitoring days from June to August 2014, and from April to June 2015.

The noise dosimeters simultaneously used two noise metrics (OSHA hearing conservation and NIOSH) as previously described.20 As each noise metric differs in terms of criterion level, exchange rate, threshold level, and time-weighting response, both noise metrics were used to determine the workers’ noise exposure acceptability in terms of the OSHA action level of 85 dBA (to which time-weighted averages (TWAs) obtained using the OSHA metric were compared) and the NIOSH REL of 85 dBA (to which TWAs from the NIOSH metric were compared). Each dosimeter was equipped with 2 data channels; channel 1 was set to the OSHA metric and channel 2 to the NIOSH metric. The eight-hour TWAs for both noise metrics were acquired. The one-minute averages for the full shift were also obtained using the OSHA metric, and were analyzed by determining the 90th, 50th, and 10th percentiles (L90, L50, and L10, respectively) overall and by university. The L90 represents the background noise level, the L50 represents the median noise level, and the L10 represents the high-end distribution of noise levels. The calibration of dosimeters was performed daily before and after monitoring.

Each monitoring day, information about tools and equipment utilized during the work shift, when they were used (ie, specific time during the day), and work break times were collected from monitored participants using activity cards. The information from each activity card was matched to the corresponding noise dosimeter data as previously described.20

Source noise measurement

The measurement of the maximum sound pressure levels (SPLs) from different groundskeeping tools and equipment as noise sources using a sound level meter, including the calibration of the sound level meter, has been previously described.20 The maximum SPL was obtained per tool or equipment operating at full throttle for one to three minutes. Information (eg, brand, model, type) on the measured tools and equipment was noted.

Data analysis

Frequencies and percentages for categorical measures were summarized, while means and standard deviations for continuous measures were determined. ANOVA and nonpaired t-tests were used to compare mean eight-hour TWA and one-minute noise exposure levels by university, month of monitoring, and use of a specific tool or equipment. Pearson chi-square test was used to evaluate differences in 85- and 90-dBA exceedence percentages among universities and monitoring months. Logistic regression was used in calculating odds ratios (OR) to evaluate the association between tools used and having noise exposure exceeding 85 or 90 dBA. The Statistical Package for the Social Sciences (SPSS version 22; SPSS Institute) was used to analyze data. P < 0.05 was considered statistically significant. This study involved human participants and has complied with the principles of the Declaration of Helsinki.

Results

Noise exposure levels

A total of 176 TWA samples were obtained from all three universities (UnivA, UnivB, and UnivC). The length of monitoring periods had an average of 523 ± 72 minutes. Groundskeepers from UnivA comprised 46.0% (n = 81) of TWAs obtained, UnivB comprised 28.4% (n = 50), and UnivC comprised 25.6% (n = 45). The groundskeepers’ eight-hour TWA noise exposure levels by university using the OSHA and NIOSH metrics are shown in Table 1. All universities (n = 176) had an overall mean OSHA and NIOSH TWA of 83.0 and 88.0 dBA, respectively. UnivB had the highest mean OSHA TWA (84.4 ± 10.1 dBA), while UnivA had the lowest (82.2 ± 9.2 dBA). The mean OSHA TWAs were not significantly different (P = 0.46) among the universities. The mean OSHA TWAs of all universities were below the OSHA action limit of 85 dBA, while the mean NIOSH TWAs exceeded the NIOSH REL of 85 dBA (Table 1). Similarly, when compared to the OSHA metric data, UnivB also had the highest mean NIOSH TWA (89.2 ± 7.3 dBA), but UnivC had the lowest (86.9 ± 6.1 dBA). The mean NIOSH TWAs were not significantly different (P = 0.23) among the universities.

Table 1.

Eight-hour TWA noise exposure level (dBA) using two noise metrics by university.

| UNIVERSITY | N | OSHA | NIOSH | ||||

|---|---|---|---|---|---|---|---|

| MEAN (± SD) | MIN | MAX | MEAN (± SD) | MIN | MAX | ||

| All | 176 | 83.0 (± 9.6) | 50.9 | 100.00 | 88.0 (± 6.7) | 67.2 | 102.9 |

| UnivA | 81 | 82.2 (± 9.2) | 50.9 | 100.0 | 87.8 (± 6.6) | 67.2 | 102.9 |

| UnivB | 50 | 84.4 (± 10.1) | 56.3 | 95.5 | 89.2 (± 7.3) | 68.8 | 98.7 |

| UnivC | 45 | 82.9 (± 9.7) | 51.3 | 95.2 | 86.9 (± 6.1) | 68.9 | 95.2 |

Table 2 compares both OSHA and NIOSH TWA levels, and the exceedence percentages under each noise metric. Exceedence percentage is defined as the percentage of TWA samples exceeding 85 and 90 dBA. The overall and university-specific mean NIOSH TWAs are significantly higher than those of the mean OSHA TWAs (P < 0.01 to P = 0.02), which may be attributed to the difference in the exchange rates used by each noise metric in calculating the TWAs. The mean of the paired differences is 5.0 ± 3.8 dBA. Overall, more than half of the OSHA (52.3%) and NIOSH TWAs (76.7%) exceeded 85 dBA (Table 2). UnivB had the highest percentages of OSHA TWAs exceeding both 85 and 90 dBA (66.0% and 28.0%, respectively), which were significantly higher (P = 0.02) than those of UnivA, which has the lowest percentages of OSHA TWAs exceeding both 85 and 90 dBA (45.7% and 13.6%, respectively). However, UnivB’s exceedence percentages were not significantly different (P = 0.09) from those of UnivC. On the other hand, using the NIOSH noise metric, UnivB also had the highest exceedence percentages of NIOSH TWAs >85 (82.0%) and >90 dBA (62.0%), while UnivC had the lowest exceedence percentage >85 (71.1%) and >90 dBA (40.0%).

Table 2.

Eight-hour TWA noise exposure levels (dBA) and exceedence percentages using two noise metrics by university.

| UNIVERSITY | n | TWA, MEAN (± SD) | EXCEEDENCE PERCENTAGE | ||||

|---|---|---|---|---|---|---|---|

| OSHA | NIOSH | OSHA | NIOSH | ||||

| >85 dBA | >90 dBA | >85 dBA | >90 dBA | ||||

| All | 176 | 83.0 (± 9.6) | 88.0 (± 6.7) | 52.3 | 20.5 | 76.7 | 47.2 |

| UnivA | 81 | 82.2 (± 9.2) | 87.8 (± 6.6) | 45.7 | 13.6 | 76.5 | 42.0 |

| UnivB | 50 | 84.4 (± 10.1) | 89.2 (± 7.3) | 66.0 | 28.0 | 82.0 | 62.0 |

| UnivC | 45 | 82.9 (± 9.7) | 86.9 (± 6.1) | 48.9 | 24.4 | 71.1 | 40.0 |

Using the OSHA metric, 92,126 minutes of noise monitoring were conducted from all 176 TWA samples (Table 3). Of these minutes of monitoring, 28.2% were >85 dBA and 21.9% > 90 dBA. The mean one-minute SPL for all universities was 85.6 ± 9.4 dBA, which exceeded the OSHA action limit of 85 dBA. UnivB (87.6 ± 10.1 dBA) has the highest average one-minute noise levels, followed by UnivC (85.3 ± 8.0 dBA), and both exceeded the OSHA 85-dBA action limit (Table 3). There is a significant difference (P < 0.01) among the mean one-minute readings by university. The 90th percentile (L90) of all one-minute noise readings was above 72.5 dBA; the 50th percentile (L50) was above 87.2 dBA; and the 10th percentile (L10) was above 97.0 dBA. Groundskeepers were monitored for noise from April to August.

Table 3.

One-minute OSHA noise readings by university (dBA).

| UNIVERSITY | COUNTa | MEAN | SD | MAX | % >85 dBA | % >90 dBA | L10 | L50 | L90 |

|---|---|---|---|---|---|---|---|---|---|

| All | 92,126 | 85.6 | 9.4 | 131.4 | 28.2 | 21.9 | 97.0 | 87.2 | 72.5 |

| UnivA | 41,829 | 84.6 | 9.6 | 131.4 | 22.7 | 17.2 | 97.2 | 83.9 | 72.2 |

| UnivB | 24,888 | 87.6 | 10.1 | 126.5 | 30.9 | 25.8 | 98.0 | 90.3 | 72.4 |

| UnivC | 25,409 | 85.3 | 8.0 | 123.9 | 34.7 | 25.7 | 93.8 | 88.1 | 73.2 |

Note:

Number of monitoring minutes obtained using OSHA noise metric.

The eight-hour TWA noise exposures of groundskeepers by month are shown in Table 4 using both noise metrics. April has the highest mean OSHA TWA (87.3 ± 3.3 dBA), while both April and August have the highest mean NIOSH TWA (93.1 dBA); July has both the lowest mean OSHA (79.5 ± 12.7 dBA) and NIOSH (86.3 ± 9.0 dBA) TWAs. However, the differences in the mean OSHA TWAs (P = 0.20) and NIOSH TWAs (P = 0.12) by month are not statistically significant. The percentages of OSHA TWAs >85 dBA by month ranged from 40.9% to 70.0%, while those of NIOSH TWAs >85 dBA ranged from 50.0% to 100%, with April having the highest percentages in both noise metrics.

Table 4.

Eight-hour TWA noise exposure levels (dBA) using two noise metrics by month.

| MONTH | N | OSHA | NIOSH | ||||

|---|---|---|---|---|---|---|---|

| MEAN (± SD) | MIN | MAX | MEAN (± SD) | MIN | MAX | ||

| All Months | 176 | 83.0 (± 9.6) | 50.9 | 100.00 | 88.0 (± 6.7) | 67.2 | 102.9 |

| April | 10 | 87.3 (± 3.3) | 82.8 | 93.0 | 93.1 (± 3.3) | 88.6 | 98.7 |

| May | 67 | 84.0 (± 9.8) | 56.3 | 95.5 | 88.1 (± 6.6) | 68.8 | 98.2 |

| June | 75 | 82.5 (± 8.8) | 51.3 | 92.8 | 87.7 (± 6.1) | 68.9 | 95.6 |

| July | 22 | 79.5 (± 12.7) | 50.9 | 100.0 | 86.3 (± 9.0) | 67.2 | 102.9 |

| August | 2 | 85.9 (± 7.5) | 82.8 | 93.0 | 93.1 (± 3.3) | 88.6 | 98.7 |

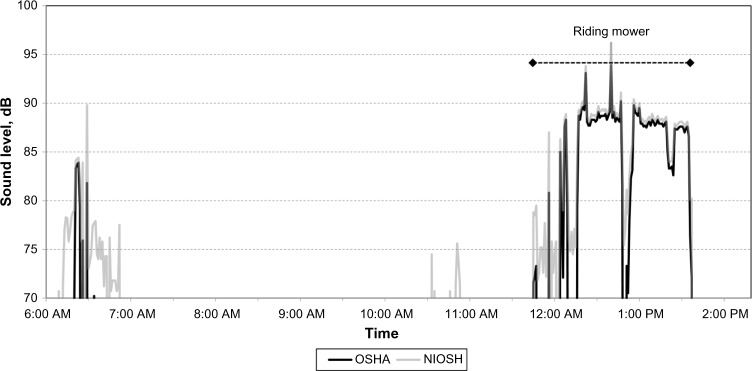

The groundskeepers identified the tools and equipment they used throughout the entire monitoring day. Table 5 compares the mean TWA noise exposures between groundskeepers who did and did not use a specific equipment or tool. The riding mower is the most reported equipment used by the groundskeepers (n = 75, 42.6%), followed by leaf blower (n = 52, 29.5%) and weed eater (n = 35, 19.9%). Both the mean OSHA (87.6 ± 4.7 dBA) and NIOSH TWAs (90.6 ± 3.5 dBA) of groundskeepers who used riding mowers during the monitoring day are significantly higher (P < 0.01) than those who did not (79.5 and 86.0 dBA, respectively; Table 5). Moreover, the use of riding mower also showed a significant association with having OSHA TWAs exceeding 85 dBA (OR = 5.97, P < 0.01) and 90 dBA (OR = 2.58, P = 0.01), and with having NIOSH TWAs exceeding 85 dBA (OR = 10.26, P < 0.01) and 90 dBA (OR = 3.03, P < 0.01). The OSHA TWAs of riding mower users ranged from 68.2 to 95.5 dBA, 76.0% of which are >85 dBA and 29.3% are >90 dBA. Individual noise exposure profiles (Figs. 1 and 2) of two workers who used a riding mower demonstrate each of their minute-by-minute noise exposures throughout their full work shift. Figure 1 shows the noise exposure profile of the groundskeeper with the highest eight-hour OSHA TWA exposure (95.5 dBA) among the riding mower users. This worker was using a riding mower for approximately seven hours (6:30 am–2:30 pm with intermittent breaks) and was exposed during use to one-minute average noise levels between 95 and 100 dBA. Figure 2 demonstrates the noise exposure profile of a groundskeeper who had one of the lowest eight-hour OSHA TWA (75.5 dBA) among the riding mower users. This worker was using a riding mower for approximately two hours (12:00–2:00 pm) continuously, exposing him to one-minute average noise levels generally between 85 and 95 dBA, while no other noisy tools were used for the rest of the work day. Among the universities, UnivB had the highest percentage (64.0%) of reported use of riding mower, followed by UnivC (37.8%) and UnivA (32.1%). More than half of the OSHA TWAs of groundskeepers who used leaf blowers (57.7%) and weed eaters (57.1%) exceeded 85 dBA.

Table 5.

TWA noise exposure level (dBA) using two noise metrics by the use of specific equipment or tool.

| EQUIPMENT/TOOL | USE | N | OSHA | NIOSH | ||

|---|---|---|---|---|---|---|

| MEAN (± SD) | P-VALUE* | MEAN (± SD) | P-VALUE* | |||

| Riding mower | Yes | 75 | 87.6 (± 4.7) | <0.01 | 90.6 (± 3.5) | <0.01 |

| No | 101 | 79.5 (± 10.8) | 86.0 (± 7.8) | |||

| Push mower | Yes | 7 | 84.1 (± 4.8) | 0.76 | 89.3 (± 3.2) | 0.61 |

| No | 169 | 82.9 (± 9.7) | 87.9 (± 6.8) | |||

| Weed eater/grass trimmer | Yes | 35 | 85.8 (± 5.4) | 0.05 | 90.1 (± 4.0) | 0.03 |

| No | 141 | 82.3 (± 10.3) | 87.5 (± 7.1) | |||

| Leaf blower | Yes | 52 | 84.4 (± 7.5) | 0.21 | 88.8 (± 5.2) | 0.27 |

| No | 124 | 82.4 (± 10.3) | 87.6 (± 7.2) | |||

| Hedge trimmer | Yes | 16 | 85.8 (± 5.7) | 0.23 | 91.1 (± 4.4) | 0.05 |

| No | 160 | 82.7 (± 9.9) | 87.7 (± 6.8) | |||

| Edger | Yes | 18 | 83.1 (± 7.9) | 0.95 | 88.4 (± 5.7) | 0.79 |

| No | 158 | 83.0 (± 9.8) | 87.9 (± 6.8) | |||

| Transport | Yes | 21 | 80.6 (± 11.1) | 0.23 | 85.9 (± 7.3) | 0.12 |

| No | 155 | 83.3 (± 9.4) | 88.3 (± 6.6) | |||

| Spray tank | Yes | 7 | 74.5 (± 12.1) | 0.02 | 82.6 (± 9.0) | 0.03 |

| No | 169 | 83.3 (± 9.3) | 88.2 (± 6.5) | |||

| Water wagon | Yes | 2 | 83.9 (± 0.8) | 0.89 | 87.9 (± 0.6) | 0.99 |

| No | 174 | 83.0 (± 9.6) | 88.0 (± 6.7) | |||

| Forklift | Yes | 1 | 90.1 (± 0.0) | 0.46 | 94.3 (± 0.0) | 0.35 |

| No | 175 | 82.9 (± 9.6) | 88.0 (± 6.7) | |||

| Backhoe | Yes | 1 | 95.2 (± 0.0) | 0.20 | 84.9 (± 0.0) | 0.65 |

| No | 175 | 82.9 (± 9.6) | 88.0 (± 6.7) | |||

| Chainsaw | Yes | 11 | 81.7 (± 7.9) | 0.65 | 89.4 (± 6.7) | 0.47 |

| No | 165 | 83.1 (± 9.7) | 87.9 (± 6.7) | |||

| Front loader | Yes | 4 | 84.5 (± 3.1) | 0.75 | 88.6 (± 4.2) | 0.85 |

| No | 172 | 82.9 (± 9.7) | 88.0 (± 6.7) | |||

| Skid steer | Yes | 4 | 84.3 (± 7.5) | 0.79 | 86.5 (± 2.1) | 0.65 |

| No | 172 | 83.0 (± 9.6) | 88.0 (± 6.8) | |||

| Chipper | Yes | 4 | 87.9 (± 2.8) | 0.30 | 96.0 (± 3.1) | 0.02 |

| No | 172 | 82.9 (± 9.7) | 87.8 (± 6.6) | |||

| Roll off truck | Yes | 3 | 79.6 (± 8.1) | 0.54 | 86.6 (± 7.3) | 0.72 |

| No | 173 | 83.0 (± 9.6) | 88.0 (± 6.7) | |||

| Others | Yes | 34 | 77.4 (± 12.9) | <0.01 | 84.3 (± 8.8) | <0.01 |

| No | 142 | 84.3 (± 8.1) | 88.9 (± 5.8) | |||

Figure 1.

Noise exposure profile of a UnivB groundskeeper with eight-hour OSHA TWA = 95.5 dBA (ie, highest TWA among the riding mower users).

Figure 2.

Noise exposure profile of a UnivB groundskeeper with eight-hour OSHA TWA = 75.5 dBA (ie, one of lowest TWAs among the riding mower users).

In contrast, both the mean OSHA (74.5 ± 12.1 dBA) and NIOSH TWAs (82.6 ± 9.0 dBA) of groundskeepers who used sprays tanks are significantly lower (P = 0.02 and P = 0.03, respectively) than those who did not (83.3 and 88.2 dBA, respectively; Table 5). Moreover, those who used equipment/tools categorized as others had significantly lower (P < 0.01) mean OSHA (77.4 ± 12.9 dBA) and NIOSH TWAs (84.3 ± 8.8 dBA) than those who did not (84.3 and 88.9 dBA, respectively; Table 5). Those who used other tools were involved in tasks, such as pruning, mulching, and watering, or were monitored during rainy days. Other tools that were commonly identified include low-noise equipment/tools (eg, hand clipper, electric lift/bucket truck), although some noisier equipment were also identified (eg, air compressor, walk-behind mower, tractor, riding blower, road blower, drill, sledge hammer).

SPLs from noise sources

Table 6 shows the maximum SPLs measured from groundskeeping equipment and tools. The STIHL MS261 chainsaw has the highest maximum SPL measured at full throttle (108.6 dBA), followed by the STIHL BR 600 leaf blower (105.9 dBA) and wood chipper (105.7 dBA). Maximum SPLs measured from all handheld tools and equipment were >85 dBA (85.5–108.6 dBA). Among the 22 ride-on equipment measured, 68.2% (n = 15) had maximum SPLs ≥85 dBA (85.0–100.8 dBA); the rest had maximum SPLs ranging from 75.5 to 84.2 dBA, and include cart, backhoe, front-end loaders, sweeper truck, and hook lift. All eight riding mowers have measured SPLs >85 dBA (88.2–95.9 dBA). A front-end loader (Mini-Cat 908) with enclosed cab and closed windows/door was measured to have the lowest SPLs (75.5 dBA), followed by a sweeper truck with enclosed cab and closed windows (76.1 dBA) and the Toro Workman 3200 cart with open cab (77.9 dBA). SPLs measured from all ride-on equipment with enclosed cab, either with open or closed windows or door, were <85 dBA (75.5–84.2 dBA). Most of the open-cab ride-on equipment (except the Toro Workman cart) had SPLs ≥85 dBA (Table 6). These maximum SPLs measured will be useful in estimating the possible worst-case scenario of a worker’s noise exposure, depending on the duration of equipment or tool use.

Table 6.

Maximum SPLs of tools and equipment used by groundskeepers.

| TOOLS AND EQUIPMENT USEDa | BRAND/MODEL | SPL (dBA) | UNIVERSITY |

|---|---|---|---|

| Hand-held Equipment/Tool | |||

| Edger | Echo BRD-280 | 99.2 | UnivA |

| Stihl FC110 | 99.9 | UnivB | |

| Stihl FC70C | 98.0 | UnivC | |

| Stihl (unknown) | 105.5 | UnivC | |

| Leaf blowerb | Stihl BR 600 | 102.5 | UnivA |

| 105.9 | UnivB | ||

| Stihl BR 500 | 94.8 | UnivA | |

| 96.4 | UnivC | ||

| Stihl BR 380 | 102.5 | UnivC | |

| Weed eater/grass trimmer | Stihl FS 90R | 98.0 | UnivA |

| Stihl FS110 | 101.5 | UnivB | |

| Chainsaw | Echo CS-530 | 105.0 | UnivA |

| Stihl MS261 | 108.6 | UnivB | |

| Hedge trimmer | Echo SHC-240 | 98.3 | UnivA |

| Push mower | Exmark Commercial 30″ | 92.4 | UnivA |

| Toro Commercial 21″ | 85.5 | UnivA | |

| Walk-behind mower | Exmark Turf Tracer HP | 97.0 | UnivA |

| Stump grinder | Vermeer | 95.3 | UnivB |

| Ride-On Equipment | |||

| Riding mowerc | Groundsmaster 4700-D | 95.9 | UnivA |

| Groundsmaster 580-D | 94.1 | UnivA | |

| Groundsmaster 345 | 94.0 | UnivA | |

| Groundsmaster 328-D | 93.5 | UnivA | |

| Ventrac 4200 | 92.4 | UnivB | |

| Toro Groundsmaster 3280-D | 88.7 | UnivC | |

| Toro Z Master Professional 7000 | 88.3 | UnivC | |

| John Deere 997 | 88.2 | UnivB | |

| Reel mowerc | John Deere 7700 | 91.0 | UnivB |

| John Deere 2653B | 88.0 | UnivB | |

| Cart | Kubotad | 83.3 | UnivB |

| Toro workman 3200c | 77.9 | UnivC | |

| Backhoe | JCB 215E series 3 | 80.6d | UnivA |

| 84.2e | UnivA | ||

| Front End Loader | Caterpillar IT14G | 78.2d | UnivA |

| Caterpillar Mini-Cat 908 | 75.5d | UnivA | |

| 81.0e | UnivA | ||

| Sweeper truck | Isuzu NPR 5.2 L | 76.1d | UnivA |

| 80.8e | UnivA | ||

| Multipurpose tractorc | Ventrac 4200 | 100.8 | UnivA |

| Tractorc | John Deere 2155 | 95.9 | UnivA |

| Multipurpose utility vehiclec | Dingo 320-D | 93.8 | UnivA |

| Forkliftc | Case 586E | 92.9 | UnivA |

| Hook liftd | International 4700 T-444E | 80.0 | UnivA |

| Skid steerc | Caterpillar 246 | 85.0 | UnivA |

| Stationary Equipment | |||

| Wood chipper | Vermeer BC1000 XL | 105.7 | UnivA |

| 102.0 | UnivB |

Notes:

Operated at full throttle;

Back pack type;

Open cab;

Enclosed cab, closed windows/door;

Enclosed cab, open window/door.

Discussion

Groundskeepers in this study were exposed to excessive noise levels that exceed the OSHA action level and NIOSH exposure limit, while a large percentage of noise measurements exceeded 85 dBA, increasing the groundkeepers’ risk to NIHL. Noise levels measured from majority of the tools and equipment commonly used by groundskeepers were >85 dBA, and include the riding mower, leaf blower, weed eater (ie, grass trimmer), edger, and hedge trimmer. These findings are similar to those in a pilot study on groundskeepers’ noise exposure in a university setting.20 This indicates that the noise exposures of groundskeepers in different universities may be comparable, which is consistent with our findings, showing no significant differences in average TWA noise exposures by university. However, the tools used were found to be significant contributors to noise exposures. Similarly, Neitzel et al suggested that tools in use and general activities are important predictors of exposure.10 TWAs obtained using the OSHA and NIOSH noise metrics were shown to be significantly different. However, the differences are lower compared to other similar studies.10,21–23 Considering that the degree of difference is related to the degree of variability in noise within the work day,10 this indicates that the groundskeepers were more likely exposed to noise levels of low variability. This may suggest that groundskeepers more likely use a single equipment throughout the day (as demonstrated by the noise exposure profile of the groundskeeper operating a riding mower for his entire work shift), or they use various equipment that produce similar noise levels (eg, weed eater, blower, and edger) during the work day. Among the OSHA TWAs of groundskeepers who used a riding mower only for the entire shift, majority (93%) had <5 dB difference and about half (54%) had <3 dB difference compared to their corresponding NIOSH TWAs. Similarly, Seshagiri found small difference between TWAs generated based on 3- and 5-dB exchange rates in truck drivers who were exposed to constant vehicle engine noise sources.22

Noise exposures of workers in the construction industry, a sector that may be comparable to groundskeeping due to similarities in some tools used and tasks performed, have been studied more extensively in the literature.10–13 In comparison, the overall percentages of the groundskeepers’ OSHA TWAs exceeding 85 and 90 dBA in this study are higher (52% and 21%, respectively) compared to those in the construction industry (40% and 13%, respectively).10 Although workers in groundskeeping and construction may share similar equipment/tools (eg, blower, backhoe, loader, forklift, bulldozer, truck, tractor), the main sources of noise exposure in construction are vastly different, which are pneumatic tools (eg, jackhammer, chipping guns) and heavy equipment (eg, backhoes, bulldozers, roller compactor, front-end loaders, graders).10,24–26 Although used occasionally, these major noise sources in construction are not the common equipment and tools among groundskeepers. This may have contributed to the differences in noise exposures between the two industries.

A pilot study identified the riding mower as one of the most commonly used equipment by groundskeepers,20 but its association with excessive noise exposure was not established. In this study, the use of riding mower was identified as a contributing factor to increased noise exposure. Riding mower use was shown to be associated both with high TWA noise exposures and high exceedence percentages (both for exceeding 85 and 90 dBA). UnivB was found to have the highest mean OSHA and NIOSH TWA exposures and the highest percentages of OSHA and NIOSH TWAs above 85 and 90 dBA. Interestingly, UnivB was also reported to have the highest percentage of riding mower use among the universities studied, which may have attributed to this university’s high TWAs and exceedence percentages. No other studies in the literature have identified the riding mower as a major source of noise among workers. However, Mallick et al identified the grass trimmer as a major source of noise exposure (with SPLs ranging from 100 to 105 dBA) among roadside maintenance workers.27 Previous SPL measurements for lawn mowers (87–99 dBA)28,29 were found to be comparable to those obtained in this study (88–96 dBA).

The use of riding mower is shown to be associated with high TWA noise exposures. However, there are several measures that can be implemented to reduce the groundskeeper’s noise exposure to acceptable levels, even when a riding mower is used. This can be achieved by reducing the operation time (eg, two hours or less instead of eight hours) and by using riding mowers that produce lower SPLs (eg, <90 dBA). Having TWA noise exposures of <85 dBA while using a riding mower was shown to be achievable as demonstrated in noise exposure profiles of a few monitored groundskeepers. For example, a UnivC worker mowed for 15 minutes, used spray tank for three hours and used no other tools for the rest of the shift, resulting on a TWA of 68.2 dBA; a UnivA worker mowed for four hours (with the highest one-minute average noise levels between 75 and 85 dBA) and a truck for two hours, resulting in a TWA of 73.4 dBA; a UnivB worker mowed for two hours and used no other tools for the rest of the shift, resulting in a TWA of 75.5 dBA. However, when reducing the operation time for riding mowers, it is important to ensure that the rest of the shift does not involve the operation of other similar noisy equipment. Otherwise, this will likely result in an unacceptable noise exposure, as demonstrated by a UnivB worker who mowed for four hours but used a weed eater (with the highest one-minute average noise levels between 95 and 100 dBA) for an additional two hours, resulting in a TWA of 95 dBA. Moreover, less noisy models of riding mowers must be obtained when purchasing new equipment, while mowers with very high SPLs (ie, ≥95 dBA) must be discarded. This preventive measure may also apply to other noisy tools and equipment.

With this study demonstrating the excessive exposure of groundskeepers to noise, it is essential for universities to establish an effective hearing conservation program to reduce the workers’ risk to NIHL, as stated by the OSHA occupational noise exposure standard.30 All three universities monitored in this study had measured TWA noise exposures >85 dBA, but only one had a hearing conservation program. Employers, managers, and employees in university workplace settings must be made fully aware of the extent of the groundskeepers’ noise exposures in these settings, as well as the preventive measures that are available to reduce the worker’s risk to NIHL.

The OSHA standard states that “feasible administrative or engineering controls shall be utilized” when employees are exposed to noise exceeding the OSHA PEL of 90 dBA, and that “if such controls fail” to reduce noise exposure within the OSHA PEL, “personal protective equipment shall be provided and used”.30 OSHA also provides recommendations to protect workers from construction noise, some of which may be applicable to reducing noise exposure among groundskeepers.30 Balanay et al described recommended noise source control and noise exposure reduction measures specifically for groundskeepers, including engineering and administrative controls, and hearing protection.20

Engineering controls include the purchase or renting of less noisy tools and equipment through the participation of universities in the NIOSH Buy Quiet Program,31 retrofitting ride-on equipment with enclosed cabs, and regular equipment maintenance.20 Many of these engineering control strategies are recommended in controlling noise in other industries, such as construction.32,33

Retrofitting the cabs of ride-on equipment with enclosure is one important strategy for reducing noise exposure of operators. Similar to a pilot study,20 this study confirmed that majority of the open-cab ride-on equipment (eg, riding mowers, tractor, forklift) produce SPLs ≥85 dBA, and that closed-cab ride-on equipment had measured SPLs ≤80 dBA. Similar results were found in studies that compared open-cab with closed-cab agricultural equipment.15,34 Moreover, it is recommended that windows and doors of existing enclosed cabs on ride-on equipment be completely closed when in use.20

Regular maintenance of equipment and tools to reduce worksite noise is also recommended in many industries, particularly in construction,12,32,33 and may also apply to groundskeeping. Proper maintenance of equipment was identified as one of the least expensive and most rewarding noise-control practices in reducing construction noise, and includes lubricating and cleaning parts, keeping saw blades sharpened, installing mufflers, changing seals, and replacing worn and/or loose bearings and other parts immediately and as necessary.12,32 University facilities managers should ensure that a regular maintenance program exists for riding mowers and other equipment, and that the maintenance schedule be followed by everyone to keep noise levels from these tools and equipment to a minimum.

Administrative controls to reduce noise exposure of groundskeepers include limiting the duration of use for noisy tools/equipment, posting noise level signs on noisy equipment/tools and around the workplace, keeping sufficient distance between groundskeepers simultaneously operating noisy equipment, and spending work breaks indoors where exposure to noise is low.20 Posting signs with expected SPLs around the workplace and on the equipment may serve as a reminder for employees to wear the needed hearing protection.12,35 Moreover, workers operating noisy equipment must have a distance of at least 50 feet from each other, since a study has shown that noise exposure can further be exacerbated when multiple weed trimmers are utilized in a common area.27 Additionally, a noise-monitoring program must be regularly conducted to identify workers who need to be enrolled in the university’s hearing conservation program.

Published data on the occupational noise exposure of groundskeepers are very limited. This study is the first of its kind to characterize the noise exposures of groundskeepers in multiple universities, which is considered a strength of this research study. The involvement of multiple sites may improve the representativeness of the study results for public universities in NC. Study findings may be used as baseline data in developing a hearing conservation program in academic institutions for groundskeepers. However, one study limitation is that some of the activity cards obtained from monitored groundskeepers were incomplete, wherein some did not specify the time of the day when they used a tool or equipment, and some failed to identify all the tools and equipment they operated throughout their work day. Other limitations include the small number of source noise measurements for equipment and tools, and lack of information on the use of hearing protection among groundskeepers.

Conclusions

Groundskeepers are occupationally exposed to noise levels exceeding the OSHA and NIOSH exposure limits. About 52% of the OSHA TWA noise exposures were above the OSHA action limit of 85 dBA, at which an effective hearing conservation program is required. Although groundskeepers and their supervisors are aware that they are exposed to noise from equipment, they may not appreciate the extent of their noise exposure and its related risk and, thus, may not realize the necessity of a hearing conservation program to reduce the NIHL risk among university groundskeepers.

No significant differences were found in the mean TWA exposure levels by university and by month when the noise monitoring was conducted. However, the use of certain equipment and tools was shown to be associated with high noise exposure levels. Therefore, it is important to ensure that the use of noisy equipment by groundskeepers be carefully scheduled to limit their exposure time and keep their TWA noise exposure <85 dBA. The university facilities supervisors have a very important role in implementing this strategy, as well as the proper training and education of the groundskeepers.

Groundskeepers monitored in this study may have noise exposures that are unique to groundskeepers working as full-time employees in the university setting. These workers’ noise exposures may not be representative of groundskeepers in different work scenarios, such as in governmental and commercial settings, because of varying factors (eg, tool and equipment type and condition, the frequency of equipment/tool use, and groundskeeper activities). Thus, these factors must be further investigated to determine their relationship to the groundskeepers’ noise exposures. Additionally, more research is warranted to further investigate the contributory factors to noise exposure and to hearing protection use among groundskeepers. This includes investigating worker demographics (eg, race and ethnicity), worker knowledge, attitudes and perception on noise exposure and hearing loss, employer-provided health and safety training received by workers, and hearing protection device use by groundskeepers, and the relationship of these contributory factors to worker noise exposure.

Acknowledgments

The authors thank all the personnel involved from the Facilities Offices and the Environmental Health and Safety Offices of each university for their assistance in participant recruitment and noise monitoring, and the groundskeepers monitored for their participation.

Footnotes

ACADEMIC EDITOR: Timothy Kelley, Editor in Chief

PEER REVIEW: Five peer reviewers contributed to the peer review report. Reviewers’ reports totaled 2,591 words, excluding any confidential comments to the academic editor.

FUNDING: This study was supported by Grant #5100435 from the National Institute for Occupational Safety and Health (NIOSH) through the North Carolina Occupational Safety and Health Education and Research Center. The contents of this article are those of the authors and do not necessarily represent the official views of the NIOSH. The authors confirm that the funder had no influence over the study design, content of the article, or selection of this journal.

COMPETING INTERESTS: Authors disclose no potential conflicts of interest.

Paper subject to independent expert blind peer review. All editorial decisions made by independent academic editor. Upon submission manuscript was subject to anti-plagiarism scanning. Prior to publication all authors have given signed confirmation of agreement to article publication and compliance with all applicable ethical and legal requirements, including the accuracy of author and contributor information, disclosure of competing interests and funding sources, compliance with ethical requirements relating to human and animal study participants, and compliance with any copyright requirements of third parties. This journal is a member of the Committee on Publication Ethics (COPE). Provenance: the authors were invited to submit this paper.

Author Contributions

Conceived and designed the experiments: GDK, JAGB. Analyzed the data: JAGB, GDK, AJM. Wrote the first draft of the manuscript: JAGB. Contributed to the writing of the manuscript: JAGB, GDK, AJM. Agreed with manuscript results and conclusions: GDK, JAGB, AJM. Jointly developed the structure and arguments for the paper: JAGB, GDK. Made critical revisions and approved the final version: JAGB, GDK, AJM. All the authors reviewed and approved the final manuscript.

REFERENCES

- 1.Bureau of Labor Statistics (BLS) Occupational Employment Statistics: Occupational Employment and Wages, May 2014: 37-3011 Landscaping and Groundskeeping Workers. Washington, DC: U.S. Department of Labor; 2015. [Accessed January 23, 2016]. Available at: http://www.bls.gov/oes/current/oes373011.htm. [Google Scholar]

- 2.Occupational Safety and Health Administration (OSHA) Safety and Health Topics: Landscaping and Horticultural Services. Washington, DC: OSHA, U.S. Department of Labor; 2015. [Accessed January 23, 2016]. Available at: https://www.osha.gov/SLTC/landscaping/index.html. [Google Scholar]

- 3.Occupational Safety and Health Administration (OSHA) Safety and Health Topics: Occupational Noise Exposure. Washington, DC: OSHA, U.S. Department of Labor; 2015. [Accessed January 23, 2016]. Available at: https://www.osha.gov/SLTC/noisehearingconservation/ [Google Scholar]

- 4.National Institute for Occupational Safety and Health (NIOSH) Noise and Hearing Loss Prevention. Atlanta, GA: NIOSH, U.S. Centers for Disease Control and Prevention; 2014. [Accessed January 23, 2016]. Available at: http://www.cdc.gov/niosh/topics/noise. [Google Scholar]

- 5.Nelson DI, Nelson RY, Concha-Barrientos M, Fingerhut M. The global burden of occupational noise-induced hearing loss. Am J Ind Med. 2005;48:446–58. doi: 10.1002/ajim.20223. [DOI] [PubMed] [Google Scholar]

- 6.Bureau of Labor Statistics (BLS) Employer-Related Workplace Injuries and Illnesses – 2013. Washington, DC: BLS, U.S. Department of Labor; 2014. [Accessed January 23, 2016]. Available at: http://www.bls.gov/news.release/archives/osh_12042014.pdf. [Google Scholar]

- 7.Medina-Tiencken K. Noise Induced Hearing Loss: A Comparison between Carpentry Workers and Landscape Workers [M.S. Thesis] Wayne, NJ: William Paterson University of New Jersey; 2013. [Google Scholar]

- 8.WorkSafeBC . Health and Safety for Landscaping and Lawn Maintenance Companies: Crew Training Talks and Employer Guide to Occupational Health and Safety Programs. Canada: WorkSafeBC; 2012. [Accessed January 23, 2016]. Available at: http://www.worksafebc.com/publications/health_and_safety/by_topic/assets/pdf/sb12.pdf. [Google Scholar]

- 9.Farm Safety Association (FSA) Safety in the Landscape Industry. Ontario: Farm Safety Association, Inc.; 2015. [Accessed January 23, 2016]. Available at: http://www.farmsafety.ca/public/manuals/manual_safety-landscape.pdf. [Google Scholar]

- 10.Neitzel R, Seixas NS, Camp J, Yost M. An assessment of occupational noise exposures in four construction trades. Am Ind Hyg Assoc J. 1999;60(6):807–17. doi: 10.1080/00028899908984506. [DOI] [PubMed] [Google Scholar]

- 11.Seixas NS, Ren K, Neitzel R, Camp J, Yost M. Noise exposure among construction electricians. Am Ind Hyg Assoc J. 2001;62(5):615–21. doi: 10.1080/15298660108984661. [DOI] [PubMed] [Google Scholar]

- 12.Suter AH. Construction noise: exposure, effects, and the potential for remediation; a review and analysis. Am Ind Hyg Assoc J. 2002;63:768–89. doi: 10.1080/15428110208984768. [DOI] [PubMed] [Google Scholar]

- 13.Fernandez MD, Quintana S, Chavarría N, et al. Noise exposure of workers of the construction sector. Appl Acoust. 2009;70(5):753–60. [Google Scholar]

- 14.McBride DI, Firth HM, Herbison GP. Noise exposure and hearing loss in agriculture: a survey of farmers and farm workers in the southland region of New Zealand. J Occup Environ Med. 2003;45(12):1281–8. doi: 10.1097/01.jom.0000100001.86223.20. [DOI] [PubMed] [Google Scholar]

- 15.Aybek A, Kamer HA, Arslan S. Personal noise exposures of operators of agricultural tractors. Appl Ergon. 2010;41(2):274–81. doi: 10.1016/j.apergo.2009.07.006. [DOI] [PubMed] [Google Scholar]

- 16.Bilski B. Exposure to audible and infrasonic noise by modern agricultural tractors operators. Appl Ergon. 2013;44(2):210–4. doi: 10.1016/j.apergo.2012.07.002. [DOI] [PubMed] [Google Scholar]

- 17.Williams W, Brumby S, Calvano A, et al. Farmers’ work-day noise exposure. Aust J Rural Health. 2015;23:67–73. doi: 10.1111/ajr.12153. [DOI] [PubMed] [Google Scholar]

- 18.Lacerda A, Quintiliano J, Lobato D, Gonçalves C, Marques J. Hearing profile of Brazilian forestry workers’ noise exposure. Int Arch Otorhinolaryngol. 2015;19:22–9. doi: 10.1055/s-0034-1382098. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Neitzel R, Yost M. Task-based assessment of occupational vibration and noise exposures in forestry workers. AIHA J. 2002;63(5):617–27. doi: 10.1080/15428110208984748. [DOI] [PubMed] [Google Scholar]

- 20.Balanay JG, Kearney GD, Mannarino AJ. Noise exposure assessment among groundskeepers in a university setting: a pilot study. J Occup Environ Hyg. 2016;13(3):193–202. doi: 10.1080/15459624.2015.1091967. [DOI] [PubMed] [Google Scholar]

- 21.Petrick ME, Royster LH, Royster JD, Reist P. Comparison of daily noise exposures in one workplace based on noise criteria recommended by ACGIH and OSHA. Am Ind Hyg Assoc J. 1996;57:924–8. doi: 10.1080/15428119691014440. [DOI] [PubMed] [Google Scholar]

- 22.Seshagiri B. Occupational noise exposure of operators of heavy trucks. Am Ind Hyg Assoc J. 1998;59:205–13. doi: 10.1080/15428119891010479. [DOI] [PubMed] [Google Scholar]

- 23.Sriwattanatamma P, Breysse P. Comparison of NIOSH noise criteria and OSHA hearing conservation criteria. Am J Ind Med. 2000;37(4):334–8. doi: 10.1002/(sici)1097-0274(200004)37:4<334::aid-ajim2>3.0.co;2-z. [DOI] [PubMed] [Google Scholar]

- 24.Schneider S, Susie P. Final Report: An Investigation of Health Hazards on a New Construction Project. Washington, DC: Center to Protect Workers’ Rights; 1993. [Google Scholar]

- 25.Schneider S, Johanning E, Belard JL, Engholm G. Noise, vibration, heat, and cold. Occup Med. 1995;10:362–83. [PubMed] [Google Scholar]

- 26.Sinclair JD, Haflidson WO. Construction noise in Ontario. Appl Occup Environ Hyg. 1995;10:457–60. [Google Scholar]

- 27.Mallick Z, Badruddin IA, Khaleed Hussain, MT Salman, Ahmed NJ, Kanesan J. Noise characteristics of grass-trimming machine engines and their effect on operators. Noise Health. 2009;11(43):98–102. doi: 10.4103/1463-1741.50694. [DOI] [PubMed] [Google Scholar]

- 28.Root KS, Schwennker C, Autenrieth D, Sandfort DR, Lipsey T, Brazile WJ. Firefighter noise exposure during training activities and general equipment use. J Occup Environ Hyg. 2013;10(3):116–21. doi: 10.1080/15459624.2012.753023. [DOI] [PubMed] [Google Scholar]

- 29.Berger EH, Neitzel R, Kladden CA. Noise NavigatorTM Sound Level Database, Version 1.8. Indianapolis, IN: 3M Personal Safety Division; 2015. [Accessed February 9, 2016]. Available at: http://multimedia.3m.com/mws/media/888553O/noise-navigator-sound-level-hearing-protection-database.pdf. [Google Scholar]

- 30.Occupational Safety and Health Administration (OSHA) 29 CFR 1910.95, Occupational Noise Exposure. Washington, DC: OSHA, U.S. Department of Labor; 2015. [Accessed January 23, 2016]. Available at: https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=9735. [Google Scholar]

- 31.National Institute for Occupational Safety and Health (NIOSH) Buy Quiet. Atlanta, GA: NIOSH, U.S. Centers for Disease Control and Prevention; 2014. [Accessed Jan. 23, 2016]. Available at: http://www.cdc.gov/niosh/topics/buyquiet/default.html. [Google Scholar]

- 32.Occupational Safety and Health Administration (OSHA) OSHA Pocket Guide: Worker Safety Series – Protecting Yourself from Noise in Construction. Washington, DC: OSHA, U.S. Department of Labor; 2011. [Accessed January 23, 2016]. Available at: https://www.osha.gov/Publications/3498noise-in-construction-pocket-guide.pdf. [Google Scholar]

- 33.Laborer’s Health and Safety Fund of North America (LHSFNA) Controlling Noise on Construction Sites. Washington, DC: LHSFNA; 2015. [Accessed January 23, 2016]. Available at: http://www.lhsfna.org/files/bpguide.pdf. [Google Scholar]

- 34.Sümer SK, Say SM, Ege F, Sabanci A. Noise exposed of the operators of combine harvesters with and without a cab. Appl Ergon. 2006;37:749–56. doi: 10.1016/j.apergo.2005.11.006. [DOI] [PubMed] [Google Scholar]

- 35.Bessette RS. Getting serious about workplace hearing protection. Chem Eng Prog. 2008;104(5):35–9. [Google Scholar]