Abstract

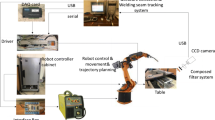

To make robotic welding more flexible, vision systems are used to detect the weld seam and plan a path for the robot to follow. In this paper an image processing technique is introduced that can automatically detect the weld seam in a “butt-weld” configuration. This method is an improvement on the existing K-Cosine algorithm. The 3D location of weld points is determined using a robot Hand-in-Eye stereo vision system. This paper will also introduce a practical method for robot and Hand/Eye calibration. The validity of these methods will be verified through experiments using a MIG welding robot.

This work is supported by the Australian Research Council under project ID LP0991108 and the Lincoln Electric Company (Australia).

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

Pachidis, T.P., Lygouras, J.N.: Vision based path generation method for a robot based arc welding system. Journal of Intelligent Robot Systems 48(3), 307–331 (2007)

Chen, S.B.: On the key technologies of intelligentized robotic welding. In: Robotic Welding, Intelligence and Automation. LNCIS, vol. 362, pp. 105–115 (2007)

Zhou, L., Lin, T., Chen, S.B.: Autonomous acquisition of seam co-ordinates for an arc welding robot based on visual servoing. Journal of Intelligent Robot Systems 47(3), 239–255 (2006)

Micallef, K., Fang, G., Dinham, M.: Automatic seam detection and path planning in robotic welding. In: Tarn, T.-J., Chen, S.-B., Fang, G. (eds.) Robotic Welding, Intelligence and Automation. LNEE, vol. 88, pp. 23–32. Springer, Heidelberg (2011)

Sun, T.: K-Cosine corner detection. Journal of Computers 3(7), 16–22 (2008)

Shi, F., Zhou, L., Lin, T., Chen, S.: Efficient weld seam detection for robotic welding from a single image. In: Robotic Welding, Intelligence and Automation. LNCIS, vol. 362, pp. 289–294 (2007)

Ryberg, A., Ericsson, M., Christiansson, A.K., et al.: Stereo vision for path correction in off-line programmed robot welding. In: IEEE International Conference on Industrial Technology, pp. 1700–1705 (2010)

Hartley, R.I., Zisserman, A.: Multiple view geometry in computer vision, 2nd edn. Cambridge University Press, Cambridge (2003)

Luo, G., Yang, X., Xu, Q.: Fast stereo matching algorithm using adaptive window. In: IEEE International Symposiums on Information Processing, pp. 25–30 (2008)

Liang, Z., Gao, H., et al.: 3D reconstruction for telerobotic welding. In: IEEE International Conference on Mechatronics and Automation, pp. 475–479 (2007)

Bouget, J.: Camera calibration toolbox for matlab (2010), http://www.vision.caltech.edu/bouguetj/calib_doc/index.html#parameters

Dinham, M., Fang, G.: Low cost simultaneous calibration of a stereo vision system and a welding robot. In: 2010 IEEE International Conference on Robotics and Biomimetrics (2010) (to appear)

Lincoln Electric, Gas metal arc welding (GMAW) guidelines. Lincoln Electric Company Publication (1995)

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2011 Springer-Verlag Berlin Heidelberg

About this paper

Cite this paper

Dinham, M., Fang, G., Zou, J.J. (2011). Experiments on Automatic Seam Detection for a MIG Welding Robot. In: Deng, H., Miao, D., Lei, J., Wang, F.L. (eds) Artificial Intelligence and Computational Intelligence. AICI 2011. Lecture Notes in Computer Science(), vol 7003. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-23887-1_49

Download citation

DOI: https://doi.org/10.1007/978-3-642-23887-1_49

Publisher Name: Springer, Berlin, Heidelberg

Print ISBN: 978-3-642-23886-4

Online ISBN: 978-3-642-23887-1

eBook Packages: Computer ScienceComputer Science (R0)