-

Notifications

You must be signed in to change notification settings - Fork 177

Home

Short description / FAQ

For updated information check my web-site: GRBL-Plotter

For use under Linux check this description by metzger100: GRBL-Plotter-Linux

A [A4988 driver] [Automation] B [Barcode] [Bellows] C [Camera] [Center finder] [Clipping] [CNC-Shield] [Coordinate system] D [Deepth sensor] [DIY control] [Drag tool] E [Edge finder] [Engraving with a soldering tip] [Egg bot] [Email notification] [Envelop] F [Fiducial correction Camera] [Fiducial correction via Probe] [Firmware] [Fonts] [Frame] G [grbl] [Grouping] H [Halftone] [Hardware] [Hatch fill] [Height map] [Hot wire cutter] I [Image] J [Jog path] K [Knife] L [Language] [Laser] [Leveling] [Light painting] M [Machine limits] [Messenger] [Multiply] N [Notifier] O [old PC] P [Path overlap] [Pen changer 1] [Pen gripper] [Polar coordinates] [Probing] [Process Automation] [Progress] [Pushbullet] Q [QR Code] R [RC-Servo] [Round off] [Rotary axis] S [Scan] [Servo] [Shapes] [Streaming protocol] [String art] T [Tangetial knife] [Tangential knife - knife holder] [Text] [Tiling] [Tool change] [Tool length] [Tool table] U [Use case] V [Variables] W [Win XP] X [XP] Y Z

Import options (new site)

Use Cases

Code Blocks

Extensions

Hardware suggestions

How to control a 2nd controller with grbl

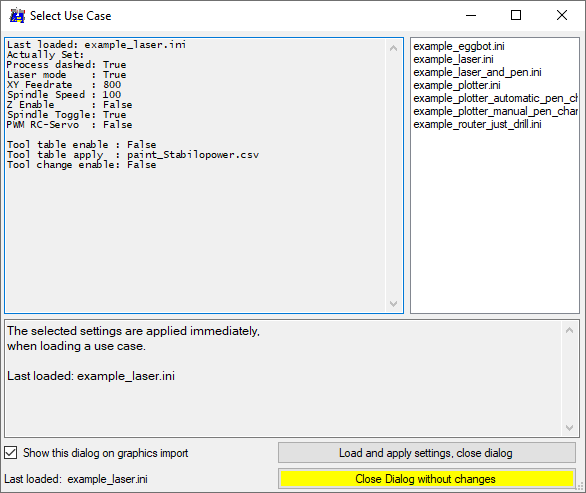

If enabled, a "Use Case" selection window pops up, when importing a SVG or DXF file.

A use-case is a preset of some import options, which can be found in [Setup - Graphics Import]

A use-case is a preset of some import options, which can be found in [Setup - Graphics Import]

Note: when changing import options in Setup and reloading a file, select the yellow button "Close Dialog without changes". Otherwise the use case would overwrite the previous changings. |

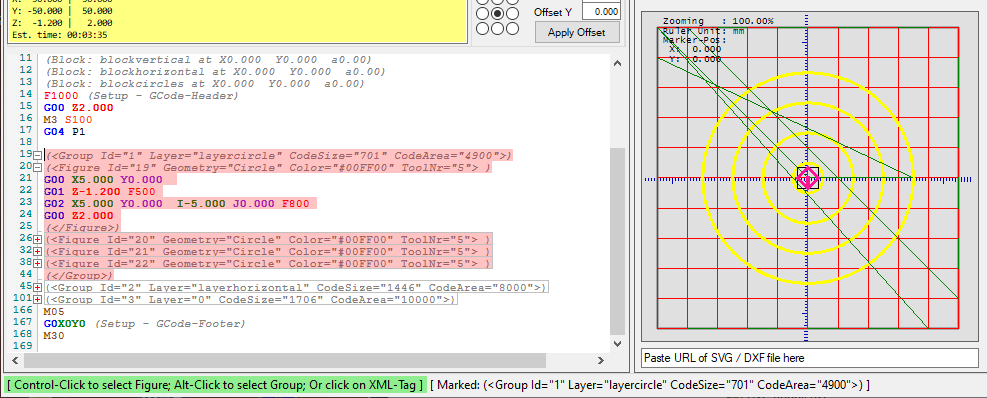

When importing data (SVG, DXF, HPGL etc.), related paths (lines, polygones, circles...) will be surrounded by a XML-Tag 'Figure'. Further on, all paths can be grouped by layer or color with the XML-Tag 'Group'. This XML-Elements I call code blocks.

Via GRBL-Plotter the order of this G-Code elements can be changed via moving or sorting of code blocks.

Inside the editor, via the 'up' and 'down' keys you can go through all 'Figures' or 'Groups' and select one by the other, the concerning path will be highlighted inside the 2D-View.

Example Code Blocks:

| |

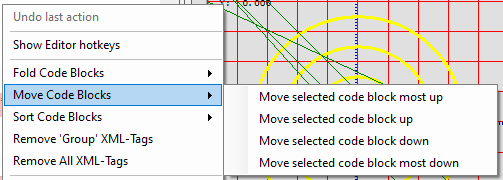

Moving Code Blocks:

|

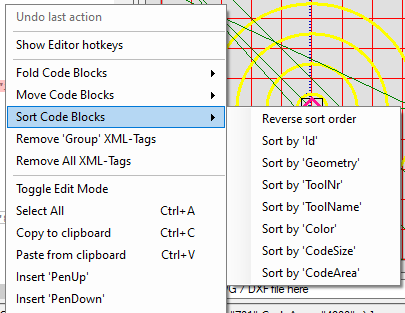

Sorting Code Blocks:

|

Extensions are user-defined scripts or programs which can be started by GRBL-Plotter.

Via the windows registry ("HKEY_CURRENT_USER\SOFTWARE\GRBL-Plotter")

- the script/program can get the current GCode import settings from GRBL-Plotter for further use

- the script/program can trigger GRBL-Plotter to get code from the clipboard, which was created before

GRBL-Plotter is polling a specific registry-key and pastes the code from the windows-clipboard on change.

Each script/program, located in \data\extensions will be listed in the menu 'G-Code Creation - Extensions' (except it starts with '_').

As an example I made a HTA script 'GCode_Conic_Spiral.hta' to generate code for a conic spiral, which I needed for an other project.

It seems that HTAs are the only type of simple script which can access registry and clipboard. Just HTML and Javascript can't do it. More complex languages like Python are more powerful but need a huge overhead - I don't like it.

GRBL-Plotter can paste codes like GCode, SVG and DXF.

https://en.wikipedia.org/wiki/HTML_Application

For most of my plotters I ordered complete sets (Arduino, CNC-Shield, motor-drivers) at ebay - just search for "Arduino CNC" or "Uno CNC" or "Nano CNC".

Note: following hardware failures I got after a while with different Arduino-clones:

- grbl status report was still sent continuously, but no other command were accepted until reset

- no response at all after sending too many jogging commands

- streaming G-Code was not possible, but manual movement

I figured out, that too high values for step-rate ($100=800) and feedrate ($110=10000) were the reason for most of the listed problems above. I made this settings to speed-up streaming on a bare controller on the desk.

I didn' t follow the rule that 'STEP' frequency must not exceed 30 kHz.

Log data:

Send/Received Data Length Free Buffer

TX G00 X6.613 Y10.170 18 21

RX G00 Z2.000 11 13

<Run|WPos:1.916,2.946,2.000|Bf:0,128|FS:1761,1000>

RX G00 X6.613 Y10.170 19 32

TX G01 Z-1.100 F500 16 32

<Run|WPos:3.011,4.536,2.412|Bf:51,128|FS:0,0>

RX G01 Z-1.100 F500 17 32

TX G01 X6.342 Y10.085 F1000 24 32

RX G01 X6.342 Y10.085 F1000 25 32

Suddenly the buffer state show 51 available blocks inside the planner buffer (Bf:51,128)

Same issue:

CNC 1610 engraver stops half way through

Commands for the 2nd GRBL will be introduced via special formatted remarks in G-Code e.g.: (^2 G90 X2) to move 2nd GRBL to position X2.

Video: https://youtu.be/fvYWyE2GBsg

Check the scripts in data/scripts script_pen_select, ..._remove, ..._pickup.

To set set G54 to zero you may use "(^2 G10 L2 P0 X0 Y0)" P0 = active coordinate system, or use P1 to set G54 explicite..

Better read this: http://linuxcnc.org/docs/html/gcode/g-code.html#gcode:g10-l2