Light Weight, Easy Formable and Non-Toxic Polymer-Based Composites for Hard X-ray Shielding: A Theoretical and Experimental Study

Abstract

:1. Introduction

- metal powders embedded in the polymeric matrices. Some of these solutions are already in commerce, e.g., tungsten-loaded polylactic acid for 3D-Printing [7];

- reduction of the effective thickness of the shielding material, which causes the reduction of the overall shielding performance;

- different mechanical properties in the same sample based only on which side is considered, a chance that could bring to fracture or lower the overall resistance;

- anisotropic shielding yields.

2. Results

2.1. Geant4 Simulations

2.2. Setup and Optimization of Sample Preparation Methods

2.3. Experimental Design

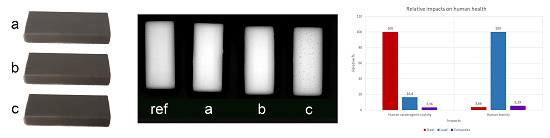

2.4. Direct Radiography

2.5. Mechanical Characterization

2.6. LCA Study

3. Discussion

4. Conclusions

5. Materials and Methods

5.1. Materials and Preparation

5.2. Analysis Methods

5.3. Modeling

5.3.1. Geant4 Simulations

5.3.2. openLCA Simulations

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Design of Experiments (DOE)

Appendix B. Geant4 Simulations

Appendix C. Sample Preparation

Appendix D. Life Cycle Assessment

References

- McCaffrey, J.P.; Shen, H.; Downton, B.; Mainegra-Hing, E. Radiation attenuation by lead and nonlead materials used in radiation shielding garments. Med. Phys. 2007, 34, 530–537. [Google Scholar] [CrossRef] [PubMed]

- Suman, S.K.; Mondal, R.K.; Kumar, J.; Dubey, K.A.; Kadam, R.M.; Melo, J.S.; Bhardwaj, Y.K.; Varshney, L. Development of highly radiopaque flexible polymer composites for X-ray imaging applications and copolymer architecture-morphology-property correlations. Eur. Polym. J. 2017, 95, 41–55. [Google Scholar] [CrossRef]

- Petrantonaki, M.; Kappas, C.; Efstathopoulos, E.P.; Theodorakos, Y.; Panayiotakis, G. Calculating shielding requirements in diagnostic X-ray departments. Br. J. Radiol. 1999, 72, 179–185. [Google Scholar] [CrossRef] [PubMed]

- Nisha, V.S.; Joseph, R. Preparation and Properties of Iodine-Doped Radiopaque Natural Rubber. J. Appl. Polym. Sci. 2007. [Google Scholar] [CrossRef]

- Wang, W.; Wei, Z.; Sang, L.; Wang, Y.; Zhang, J.; Bian, Y. Development of X-ray opaque poly (lactic acid) end-capped by triiodobenzoic acid towards non-invasive micro-CT imaging biodegradable embolic microspheres. Eur. Polym. J. 2018, 108, 337–347. [Google Scholar] [CrossRef]

- Houston, K.R.; Brosnan, S.M.; Burk, L.M.; Lee, Y.Z.; Luft, J.C.; Ashby, V.S. Iodinated Polyesters as a Versatile Platform for Radiopaque Biomaterials. J. Polym. Sci. Part A Polym. Chem. 2017, 2171–2177. [Google Scholar] [CrossRef]

- Kazempour, M.; Saeedimoghadam, F.; Shekoohi Shooli, N.S. Assessment of the Radiation Attenuation Properties of Several Lead Free Composites by Monte Carlo Simulation. J. Biomed. Phys. Eng. 2015, 5, 67–76. [Google Scholar] [PubMed]

- Nambiar, S.; Osei, E.K.; Yeow, J.T. Polymer nanocomposite-based shielding against diagnostic X-rays. J. Appl. Polym. Sci. 2013, 127, 4939–4946. [Google Scholar] [CrossRef]

- Ambika, M.R.; Nagaiah, N.; Suman, S.K. Role of bismuth oxide as a reinforcer on gamma shielding ability of unsaturated polyester based polymer composites. J. Appl. Polym. Sci. 2017, 134, 1–7. [Google Scholar] [CrossRef]

- Mirji, R.; Lobo, B. Radiation shielding materials: A brief review on methods, scope and significance. In Proceedings of the National Conference on Advances in VLS and Microelectronics, Huballi, India, 27 January 2017. [Google Scholar]

- Omar, K.; Al-khazaleh, K.A.; Saadi, S.A. Barium Sulfate Epoxy Mixture Effects on Attenuation of Short Wavelength Barium Sulfate Epoxy Mixture Effects on Attenuation of Short Wavelength Radiation. Nuclear Radiat. Phys. 2015, 80, 31333–31338. [Google Scholar]

- Prolongo, S.G.; Moriche, R.; Sánchez, M.; Ureña, A. Self-stratifying and orientation of exfoliated few-layer graphene nanoplatelets in epoxy composites. Compos. Sci. Technol. 2013, 85, 136–141. [Google Scholar] [CrossRef]

- Altomare, A.; Corriero, N.; Cuocci, C.; Falcicchio, A.; Moliterni, A.; Rizzi, R. QUALX2.0: A qualitative phase analysis software using the freely available database POWCOD. J. Appl. Crystallogr. 2015, 48, 598–603. [Google Scholar] [CrossRef]

- Coelho, A.A. TOPAS and TOPAS-Academic: An optimization program integrating computer algebra and crystallographic objects written in C++. J. Appl. Crystallogr. 2018, 51, 210–218. [Google Scholar] [CrossRef] [Green Version]

- Gražulis, S.; Chateigner, D.; Downs, R.T.; Yokochi, A.F.T.; Quirós, M.; Lutterotti, L.; Manakova, E.; Butkus, J.; Moeck, P.; Le Bail, A. Crystallography Open Database—An open-access collection of crystal structures. J. Appl. Crystallogr. 2009, 42, 726–729. [Google Scholar] [CrossRef] [PubMed]

- Available online: http://www.openlca.org (accessed on 23 January 2020).

- Available online: https://www.ecoinvent.org (accessed on 23 January 2020).

- Agostinelli, S.; Allison, J.; Amako, K.; Apostolakis, J.; Araujo, H.; Arce, P.; Asai, M.; Axen, D.; Banerjee, S.; Barrand, G.; et al. GEANT4—A simulation toolkit. Nuclear Instruments and Methods in Physics Research, Section A: Accelerators, Spectrometers, Detectors and Associated Equipment; Elsevier: Amsterdam, The Netherlands, 2003; Volume 506, pp. 250–303. [Google Scholar] [CrossRef] [Green Version]

- Allison, J.; Amako, K.; Apostolakis, J.; Arce, P.; Asai, M.; Aso, T.; Bagli, E.; Bagulya, A.; Banerjee, S.; Barrand, G.; et al. Recent developments in GEANT4. Nuclear Instruments and Methods in Physics Research, Section A: Accelerators, Spectrometers, Detectors and Associated Equipment; Elsevier: Amsterdam, The Netherlands, 2016; Volume 835, pp. 186–225. [Google Scholar] [CrossRef]

- ISO. 14040:2006, Environmental Management—Life Cycle Assessment—Principles and Framework; European Union: Brussels, Belgium, 2006. [Google Scholar]

- ISO. 14044:2006, Environmental Management—Life Cycle Assessment—Requirements and Guidelines; European Union: Brussels, Belgium, 2006. [Google Scholar]

- JRC. International Reference Life Cycle Data System (ILCD) Handbook, General Guide for Life Cycle Assessment, Detailed Guidance; European Commission: Brussels, Belgium, 2010. [Google Scholar] [CrossRef]

| BaSO4 Samples | ||

|---|---|---|

| Sample Name | BaSO4 Weight % | Epoxy Weight % |

| 1 | 0 | 100 |

| 2 | 30 | 70 |

| 3 | 40 | 60 |

| 4 | 50 | 50 |

| 5 | 60 | 40 |

| 6 | 70 | 30 |

| 7 | 80 | 20 |

| 8 | 80 | 20 |

| 9 | 85 | 15 |

| BaSO4–Bi2O3 Samples | |||

|---|---|---|---|

| Sample Name | BaSO4 Weight % | Bi2O3 Weight % | Epoxy Weight % |

| a | 20 | 60 | 20 |

| b | 40 | 40 | 20 |

| c | 60 | 20 | 20 |

| d | 40 | 20 | 40 |

| e | 20 | 20 | 60 |

| f | 20 | 40 | 40 |

| Sample | Average Stress at Break Point | Standard Deviation | Variation Coefficient % |

|---|---|---|---|

| Epoxy resin | 28.68 MPa | ±1.98 MPa | 6.91% |

| a | 9.654 MPa | ±5.34 MPa | 55.30% |

| b | 14.12 MPa | ±1.19 MPa | 8.46% |

| c | 5.06 MPa | ±1.62 MPa | 31.99% |

| Impact Category | Composite | Lead | Steel | Unit |

|---|---|---|---|---|

| Fine particulate matter formation | kg PM2.5 eq | |||

| Fossil resource scarcity | kg oil eq | |||

| Freshwater ecotoxicity | kg 1,4-DCB | |||

| Freshwater eutrophication | kg P eq | |||

| Global warming | kg CO2 eq | |||

| Human carcinogenic toxicity | kg 1,4-DCB | |||

| Human non-carcinogenic toxicity | kg 1,4-DCB | |||

| Ionizing radiation | kBq 60Co eq | |||

| Land use | ma crop eq | |||

| Marine ecotoxicity | kg 1,4-DCB | |||

| Marine eutrophication | kg N eq | |||

| Mineral resource scarcity | kg Cu eq | |||

| Ozone formation, Human health | kg NOx eq | |||

| Ozone formation, Terrestrial ecosystems | kg NOx eq | |||

| Stratospheric ozone depletion | kg CFC11 eq | |||

| Terrestrial acidification | kg SO2 eq | |||

| Terrestrial ecotoxicity | kg 1,4-DCB | |||

| Water consumption | m |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lopresti, M.; Alberto, G.; Cantamessa, S.; Cantino, G.; Conterosito, E.; Palin, L.; Milanesio, M. Light Weight, Easy Formable and Non-Toxic Polymer-Based Composites for Hard X-ray Shielding: A Theoretical and Experimental Study. Int. J. Mol. Sci. 2020, 21, 833. https://doi.org/10.3390/ijms21030833

Lopresti M, Alberto G, Cantamessa S, Cantino G, Conterosito E, Palin L, Milanesio M. Light Weight, Easy Formable and Non-Toxic Polymer-Based Composites for Hard X-ray Shielding: A Theoretical and Experimental Study. International Journal of Molecular Sciences. 2020; 21(3):833. https://doi.org/10.3390/ijms21030833

Chicago/Turabian StyleLopresti, Mattia, Gabriele Alberto, Simone Cantamessa, Giorgio Cantino, Eleonora Conterosito, Luca Palin, and Marco Milanesio. 2020. "Light Weight, Easy Formable and Non-Toxic Polymer-Based Composites for Hard X-ray Shielding: A Theoretical and Experimental Study" International Journal of Molecular Sciences 21, no. 3: 833. https://doi.org/10.3390/ijms21030833