Abstract

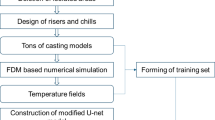

The manufacture of large wind turbine blades requires well-controlled processing conditions to prevent defect formation and thus produce high-quality composite blades. While the physics-based models provide accurate computational capabilities for the resin infusion and curing process for the glass fiber composites, they suffer from high computational costs, making them infeasible for fast optimization computation and process control during manufacturing. In light of the limitations, we describe a machine learning (ML) approach that employs a deep convolutional and recurrent neural network model to predict the spatio-temporal temperature distribution during the vacuum assisted resin infusion molding (VARIM) process. The ML model is trained with the “big data” generated from the physics-based high-fidelity simulations. Once fully trained, it serves as a digital twin of the blade manufacturing process. Validation is made by comparing simulation results with experimental data on a unidirectional glass fiber composite laminate plate (44 plies, 2 m long and 0.5 m wide). The trained and validated ML model is then extended to evaluate the role of critical VARIM processing parameters on temperature distribution. With the predictive accuracy of 94%, at over 100 times faster computational speed than the physics-based simulations, the ML approach established herein provides a general framework for a digital twin for temperature distribution in the composite manufacturing process.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Data availability

Datasets, codes, and models used in this paper have been uploaded to GitHub as a reference for readers interested in performing additional analysis. Weblink to GitHub: https://github.com/Runyu-Zhang/Spatio-temporal-temperature-prediction-for-VARIM-process

References

Abadi, M., Agarwal, A., Barham, P., Brevdo, E., Chen, Z., Citro, C., et al. (2016). TensorFlow: Large-scale machine learning on heterogeneous distributed systems. arXiv. https://doi.org/10.48550/arxiv.1603.04467

Abiodun, O. I., Jantan, A., Omolara, A. E., Dada, K. V., Mohamed, N. A. E., & Arshad, H. (2018). State-of-the-art in artificial neural network applications: A survey. Heliyon, 4(11), e00938. https://doi.org/10.1016/J.HELIYON.2018.E00938

Albawi, S., Mohammed, T. A., & Al-Zawi, S. (2018). Understanding of a convolutional neural network. Proceedings of 2017 International Conference on Engineering and Technology, ICET 2017, 2018 pp. 1–6. https://doi.org/10.1109/ICENGTECHNOL.2017.8308186

Amini Niaki, S., Haghighat, E., Campbell, T., Poursartip, A., & Vaziri, R. (2021). Physics-informed neural network for modelling the thermochemical curing process of composite-tool systems during manufacture. Computer Methods in Applied Mechanics and Engineering, 384, 113959. https://doi.org/10.1016/J.CMA.2021.113959

Arnold, F., Demallie, I., Florence, L., & Kashinski, D. O. (2015). Method for collecting thermocouple data via secured shell over a wireless local area network in real time. Review of Scientific Instruments, 86(3), 035112. https://doi.org/10.1063/1.4915490

Barari, B., Simacek, P., Yarlagadda, S., Crane, R. M., & Advani, S. G. (2019). Prediction of process-induced void formation in anisotropic Fiber-reinforced autoclave composite parts. International Journal of Material Forming, 13(1), 143–158. https://doi.org/10.1007/S12289-019-01477-4

Bender, D., Schuster, J., & Heider, D. (2006). Flow rate control during vacuum-assisted resin transfer molding (VARTM) processing. Composites Science and Technology, 66(13), 2265–2271. https://doi.org/10.1016/J.COMPSCITECH.2005.12.008

Chen, Y., Wang, Y., Dong, Z., Su, J., Han, Z., Zhou, D., et al. (2021). 2-D regional short-term wind speed forecast based on CNN-LSTM deep learning model. Energy Conversion and Management, 244, 114451. https://doi.org/10.1016/J.ENCONMAN.2021.114451

Chiu, H. T., Yu, B., Chen, S. C., & Lee, L. J. (2000). Heat transfer during flow and resin reaction through fiber reinforcement. Chemical Engineering Science, 55(17), 3365–3376. https://doi.org/10.1016/S0009-2509(00)00004-X

Cotrell, J., Musial, W., & Hughes, S. (2006). Necessity and requirements of a collaborative effort to develop a large wind turbine blade test facility in North America. https://doi.org/10.2172/882539

Department of Energy (2022). Wind Turbines: the Bigger, the Better. https://www.energy.gov/eere/articles/wind-turbines-bigger-better

Devillard, M., Hsiao, K. T., & Advani, S. G. (2005). Flow sensing and control strategies to address race-tracking disturbances in resin transfer molding—part II: Automation and validation. Composites Part A: Applied Science and Manufacturing, 36(11), 1581–1589. https://doi.org/10.1016/J.COMPOSITESA.2004.04.009

Devlin, J., Chang, M. W., Lee, K., & Toutanova, K. (2018). BERT: Pre-training of Deep Bidirectional Transformers for Language Understanding. NAACL HLT 2019 - 2019 Conference of the North American Chapter of the Association for Computational Linguistics: Human Language Technologies - Proceedings of the Conference, 1, pp. 4171–4186. https://doi.org/10.48550/arxiv.1810.04805

Djavadifar, A., Graham-Knight, J. B., Kӧrber, M., Lasserre, P., & Najjaran, H. (2021). Automated visual detection of geometrical defects in composite manufacturing processes using deep convolutional neural networks. Journal of Intelligent Manufacturing. https://doi.org/10.1007/S10845-021-01776-1/TABLES/7

Ersoy, N., & Tugutlu, M. (2010). Cure kinetics modeling and cure shrinkage behavior of a thermosetting composite. Polymer Engineering & Science, 50(1), 84–92. https://doi.org/10.1002/PEN.21514

Eum, S. H., Kageyama, K., Murayama, H., Uzawa, K., Ohsawa, I., Kanai, M., et al. (2007). Structural health monitoring using fiber optic distributed sensors for vacuum-assisted resin transfer molding. Smart Materials and Structures, 16(6), 2627. https://doi.org/10.1088/0964-1726/16/6/067

Fu, Y., & Yao, X. (2022). A review on manufacturing defects and their detection of fiber reinforced resin matrix composites. Composites Part C: Open Access, 8, 100276. https://doi.org/10.1016/J.JCOMC.2022.100276

Gers, F. A., Schmidhuber, J., & Cummins, F. (2000). Learning to forget: Continual prediction with LSTM. Neural Computation, 12(10), 2451–2471. https://doi.org/10.1162/089976600300015015

Gers, F. A., Schraudolph, N. N., & Schmidhuber, J. (2002). Learning precise timing with LSTM recurrent networks. Journal of machine learning research, 3(Aug), 115–143.

Gokce, A., Chohra, M., Advani, S. G., & Walsh, S. M. (2005). Permeability estimation algorithm to simultaneously characterize the distribution media and the fabric preform in vacuum assisted resin transfer molding process. Composites Science and Technology, 65(14), 2129–2139. https://doi.org/10.1016/J.COMPSCITECH.2005.05.012

Goli, E., Vyas, S., Koric, S., Sobh, N., & Geubelle, P. H. (2020). ChemNet: A deep neural network for advanced composites manufacturing. Journal of Physical Chemistry B, 124(42), 9428–9437. https://doi.org/10.1021/ACS.JPCB.0C03328

Goodfellow, I., Bengio, Y., & Courville, A. (2016). Deep learning. MIT press.

Govignon, Q., Bickerton, S., & Kelly, P. A. (2008). Simulation of the complete resin infusion process. In 9th International Conference on Flow Processes in Composite Materials.

Griffith, D. T., & Ashwill, T. D. (2011). The Sandia 100-meter all-glass baseline wind turbine blade: SNL100–00. Informe Técnico, Sandia National Laboratories.

He, K., Chen, X., Xie, S., Li, Y., Dollár, P., & Girshick, R. (2022). Masked autoencoders are scalable vision learners. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition (pp. 16000–16009).

He, K., Zhang, X., Ren, S., & Sun, J. (2015). Deep Residual Learning for Image Recognition. Proceedings of the IEEE Computer Society Conference on Computer Vision and Pattern Recognition, 2016-December, 770–778. https://doi.org/10.48550/arxiv.1512.03385

Hinton, G. E., Krizhevsky, A., & Wang, S. D. (2011). Transforming auto-encoders. In International conference on artificial neural networks. Springer, Berlin (pp. 44–51).

Hinton, G. E., Osindero, S., & Teh, Y. W. (2006). A fast learning algorithm for deep belief nets. Neural Computation, 18(7), 1527–1554. https://doi.org/10.1162/NECO.2006.18.7.1527

Hochreiter, S. (2011). The vanishing gradient problem during learning recurrent neural nets and problem solutions. International Journal of Uncertainty, Fuzziness and Knowledge-Based Systems, 6(2), 107–116. https://doi.org/10.1142/S0218488598000094

Hochreiter, S., & Schmidhuber, J. (1997). Long Short-Term Memory. Neural Computation, 9(8), 1735–1780. https://doi.org/10.1162/NECO.1997.9.8.1735

Hsiao, K.-T., & Heider, D. (2012). Vacuum assisted resin transfer molding (VARTM) in polymer matrix composites. Manufacturing Techniques for Polymer Matrix Composites (PMCs). https://doi.org/10.1533/9780857096258.3.310

Hsiao, K. T., Mathur, R., Advani, S. G., Gillespie, J. W., & Fink, B. K. (2000). A Closed Form Solution for Flow During the Vacuum Assisted Resin Transfer Molding Process. Journal of Manufacturing Science and Engineering, 122(3), 463–475. https://doi.org/10.1115/1.1285907

Jain, A. K., Mao, J., & Mohiuddin, K. M. (1996). Artificial neural networks: A tutorial. Computer, 29(3), 31–44. https://doi.org/10.1109/2.485891

Jumper, J., Evans, R., Pritzel, A., Green, T., Figurnov, M., Ronneberger, O., et al. (2021). Highly accurate protein structure prediction with AlphaFold. Nature, 596(7873), 583–589. https://doi.org/10.1038/s41586-021-03819-2

Kaelbling, L. P., Littman, M. L., & Moore, A. W. (1996). Reinforcement Learning: A Survey. Journal of Artificial Intelligence Research, 4, 237–285. https://doi.org/10.1613/JAIR.301

Kamal, M. R., & Ryan, M. E. (1980). The behavior of thermosetting compounds in injection molding cavities. Polymer Engineering & Science, 20(13), 859–867. https://doi.org/10.1002/PEN.760201305

Kamal, M. R., & Sourour, S. (1973). Kinetics and thermal characterization of thermoset cure. Polymer Engineering & Science, 13(1), 59–64. https://doi.org/10.1002/PEN.760130110

Kedari, V. R., Farah, B. I., & Hsiao, K. T. (2011). Effects of vacuum pressure, inlet pressure, and mold temperature on the void content, volume fraction of polyester/e-glass fiber composites manufactured with VARTM process. Journal of Composite Materials, 45(26), 2727–2742. https://doi.org/10.1177/0021998311415442

Kingma, D. P., & Ba, J. L. (2014). Adam: A Method for Stochastic Optimization. 3rd International Conference on Learning Representations, ICLR 2015 - Conference Track Proceedings. https://doi.org/10.48550/arxiv.1412.6980

Kingma, D. P., & Welling, M. (2019). An Introduction to Variational Autoencoders. Foundations and Trends® in Machine Learning, 12(4), 307–392. https://doi.org/10.1561/2200000056

Kravchenko, O. G., Li, C., Strachan, A., Kravchenko, S. G., & Pipes, R. B. (2014). Prediction of the chemical and thermal shrinkage in a thermoset polymer. Composites Part a: Applied Science and Manufacturing, 66, 35–43. https://doi.org/10.1016/J.COMPOSITESA.2014.07.002

Krizhevsky, A., Sutskever, I., & Hinton, G. E. (2017). Imagenet classification with deep convolutional neural networks. Communications of the ACM, 60(6), 84–90.

Krogh, A. (2008). What are artificial neural networks? Nature Biotechnology, 26(2), 195–197. https://doi.org/10.1038/nbt1386

Kusiak, A. (2017). Smart manufacturing must embrace big data (pp. 23–25). Taylor & Francis.

Kusiak, A. (2017). Smart manufacturing (pp. 508–517). Taylor & Francis.

Lecun, Y., Bengio, Y., & Hinton, G. (2015). Deep learning. Nature, 521(7553), 436–444. https://doi.org/10.1038/nature14539

Lipton, Z. C., Berkowitz, J., & Elkan, C. (2015). A Critical review of recurrent neural networks for sequence learning. arXiv. https://doi.org/10.48550/arxiv.1506.00019

Liu, C., Zhu, H., Tang, D., Nie, Q., Li, S., Zhang, Y., & Liu, X. (2022). A transfer learning CNN-LSTM network-based production progress prediction approach in IIoT-enabled manufacturing.https://doi.org/10.1080/00207543.2022.2056860

Ma, L., Athreya, S. R., Mehta, R., Barpanda, D., & Shafi, A. (2017). Numerical modeling and experimental validation of nonisothermal resin infusion and cure processes in large composites. Journal of Reinforced Plastics and Composites, 36(10), 780–794. https://doi.org/10.1177/0731684417691673

Mal, O., Couniot, A., & Dupret, F. (1998). Non-isothermal simulation of the resin transfer moulding press. Composites Part A: Applied Science and Manufacturing, 29(1–2), 189–198. https://doi.org/10.1016/S1359-835X(97)00065-1

Mathuw, R., Advani, S. G., Heider, D., Hoffmann, C., Gillespie, J. W., & Fink, B. K. (2001). Flow front measurements and model validation in the vacuum assisted resin transfer molding process. Polymer Composites, 22(4), 477–490. https://doi.org/10.1002/PC.10553

Matsuzaki, R., Kobayashi, S., Todoroki, A., & Mizutani, Y. (2011). Control of resin flow/temperature using multifunctional interdigital electrode array film during a VaRTM process. Composites Part A: Applied Science and Manufacturing, 42(7), 782–793. https://doi.org/10.1016/J.COMPOSITESA.2011.03.004

Matsuzaki, R., Kobayashi, S., Todoroki, A., & Mizutani, Y. (2013). Flow control by progressive forecasting using numerical simulation during vacuum-assisted resin transfer molding. Composites Part A: Applied Science and Manufacturing, 45, 79–87. https://doi.org/10.1016/J.COMPOSITESA.2012.09.014

Meng, M., Chua, Y. J., Wouterson, E., & Ong, C. P. K. (2017). Ultrasonic signal classification and imaging system for composite materials via deep convolutional neural networks. Neurocomputing, 257, 128–135. https://doi.org/10.1016/J.NEUCOM.2016.11.066

Mnih, V., Kavukcuoglu, K., Silver, D., Graves, A., Antonoglou, I., Wierstra, D., & Riedmiller, M. (2013). Playing Atari with Deep Reinforcement Learning. https://doi.org/10.48550/arxiv.1312.5602

Nalla, A. R., Fuqua, M., Glancey, J., & Lelievre, B. (2007). A multi-segment injection line and real-time adaptive, model-based controller for vacuum assisted resin transfer molding. Composites Part A: Applied Science and Manufacturing, 38(3), 1058–1069. https://doi.org/10.1016/J.COMPOSITESA.2006.06.021

Nicolay, P., Matloub, R., Bardong, J., Mazzalai, A., & Muralt, P. (2017). A concept of wireless and passive very-high temperature sensor. Applied Physics Letters, 110(18), 184104. https://doi.org/10.1063/1.4983085

Nielsen, D. R., & Pitchumani, R. (2002). Closed-loop flow control in resin transfer molding using real-time numerical process simulations. Composites Science and Technology, 62(2), 283–298. https://doi.org/10.1016/S0266-3538(01)00213-5

Olah, C. (2015). Understanding lstm networks. https://colah.github.io/

OpenAI. (2022). https://openai.com/

Ouahbi, T., Saouab, A., Bréard, J., Ouagne, P., & Chatel, S. (2007). Modelling of hydro-mechanical coupling in infusion processes. Composites Part a: Applied Science and Manufacturing, 38(7), 1646–1654. https://doi.org/10.1016/J.COMPOSITESA.2007.03.002

Pathak, D., Krahenbuhl, P., Donahue, J., Darrell, T., Efros, A. A. (2016). Context encoders: Feature learning by inpainting. In Proceedings of the IEEE conference on computer vision and pattern recognition (pp. 2536–2544).

Pfrommer, J., Zimmerling, C., Liu, J., Kärger, L., Henning, F., & Beyerer, J. (2018). Optimisation of manufacturing process parameters using deep neural networks as surrogate models. Procedia CIRP, 72, 426–431. https://doi.org/10.1016/J.PROCIR.2018.03.046

Potter, K. D. (2009). Understanding the origins of defects and variability in composites manufacture. In International conference on composite materials (ICCM)-17, Edinburgh (p. 18).

Ramesh, A., Pavlov, M., Goh, G., Gray, S., Voss, C., Radford, A., ... & Sutskever, I. (2021). Zero-shot text-to-image generation. In International Conference on Machine Learning. PMLR (pp. 8821–8831)

Reed, S., Zolna, K., Parisotto, E., Colmenarejo, S. G., Novikov, A., Barth-Maron, G., ... , de Freitas, N. (2022). A generalist agent. arXiv preprint arXiv:2205.06175.

Rumelhart, D. E., Hinton, G. E., & Williams, R. J. (1985). Learning internal representations by error propagation. California Univ San Diego La Jolla Inst for Cognitive Science.

Rumelhart, D. E., Hinton, G. E., & Williams, R. J. (1986). Learning representations by back-propagating errors. Nature, 323(6088), 533–536. https://doi.org/10.1038/323533a0

Samborsky, D. D., Agastra, P., & Mandell, J. F. (2010). Fatigue trends for wind blade infusion resins and fabrics. Collection of Technical Papers - AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference. https://doi.org/10.2514/6.2010-2820

Sharma, A., Vans, E., Shigemizu, D., Boroevich, K. A., & Tsunoda, T. (2019). DeepInsight: A methodology to transform a non-image data to an image for convolution neural network architecture. Scientific Reports, 9(1), 1–7. https://doi.org/10.1038/s41598-019-47765-6

Shojaei, A., Ghaffarian, S. R., & Karimian, S. M. H. (2003). Modeling and simulation approaches in the resin transfer molding process: A review. Polymer Composites, 24(4), 525–544. https://doi.org/10.1002/PC.10050

Siddig, N. A., Binetruy, C., Syerko, E., Simacek, P., & Advani, S. (2018). A new methodology for race-tracking detection and criticality in resin transfer molding process using pressure sensors. Journal of Composite Materials, 52(29), 4087–4103.

Silver, D., Huang, A., Maddison, C. J., Guez, A., Sifre, L., van den Driessche, G., et al. (2016). Mastering the game of Go with deep neural networks and tree search. Nature, 529(7587), 484–489. https://doi.org/10.1038/nature16961

Silver, D., Schrittwieser, J., Simonyan, K., Antonoglou, I., Huang, A., Guez, A., et al. (2017). Mastering the game of Go without human knowledge. Nature, 550(7676), 354–359. https://doi.org/10.1038/nature24270

Simacek, P., Eksik, Ö., Heider, D., Gillespie, J. W., & Advani, S. (2012). Experimental validation of post-filling flow in vacuum assisted resin transfer molding processes. Composites Part A: Applied Science and Manufacturing, 43(3), 370–380. https://doi.org/10.1016/J.COMPOSITESA.2011.10.002

Simacek, P., Heider, D., Gillespie, J. W., & Advani, S. (2009). Post-filling flow in vacuum assisted resin transfer molding processes: Theoretical analysis. Composites Part A: Applied Science and Manufacturing, 40(6–7), 913–924. https://doi.org/10.1016/J.COMPOSITESA.2009.04.018

Simonyan, K., & Zisserman, A. (2014). Very deep convolutional networks for large-scale image recognition. 3rd International Conference on Learning Representations, ICLR 2015 - Conference Track Proceedings. https://doi.org/10.48550/arxiv.1409.1556

Struzziero, G., & Teuwen, J. J. E. (2019). Effect of convection coefficient and thickness on optimal cure cycles for the manufacturing of wind turbine components using VARTM. Composites Part a: Applied Science and Manufacturing, 123, 25–36. https://doi.org/10.1016/J.COMPOSITESA.2019.04.024

Sun, X., Li, S., & Lee, L. J. (1998). Mold filling analysis in vacuum-assisted resin transfer molding. Part I: SCRIMP based on a high-permeable medium. Polymer Composites, 19(6), 807–817. https://doi.org/10.1002/PC.10155

Sutton, R. S., & Barto, A. G. (2018). Reinforcement learning: An introduction. MIT press.

Szarski, M., & Chauhan, S. (2023). Instant flow distribution network optimization in liquid composite molding using deep reinforcement learning. Journal of Intelligent Manufacturing, 34(1), 197–218.

Tao, F., Qi, Q., Liu, A., & Kusiak, A. (2018). Data-driven smart manufacturing. Journal of Manufacturing Systems, 48, 157–169. https://doi.org/10.1016/J.JMSY.2018.01.006

Tifkitsis, K. I., & Skordos, A. A. (2020). Real time uncertainty estimation in filling stage of resin transfer molding process. Polymer Composites, 41(12), 5387–5402. https://doi.org/10.1002/PC.25803

Upadhyaya, P., Roy, S., Haque, M. H., & Lu, H. (2013). A novel numerical–experimental approach for predicting delamination in high temperature polymer matrix composites. Composite Structures, 104, 118–124. https://doi.org/10.1016/J.COMPSTRUCT.2013.04.008

Vincent, P., Larochelle, H., Lajoie, I., Bengio, Y., & Manzagol, P.-A. (2010). Stacked denoising autoencoders: Learning useful representations in a deep network with a local denoising criterion. The Journal of Machine Learning Research. https://doi.org/10.5555/1756006.1953039

Wisnom, M. R., Gigliotti, M., Ersoy, N., Campbell, M., & Potter, K. D. (2006). Mechanisms generating residual stresses and distortion during manufacture of polymer–matrix composite structures. Composites Part A: Applied Science and Manufacturing, 37(4), 522–529. https://doi.org/10.1016/J.COMPOSITESA.2005.05.019

Wurman, P. R., Barrett, S., Kawamoto, K., MacGlashan, J., Subramanian, K., Walsh, T. J., et al. (2022). Outracing champion gran turismo drivers with deep reinforcement learning. Nature, 602(7896), 223–228. https://doi.org/10.1038/s41586-021-04357-7

Yun, M.-Y., Lopez, E., Chinesta, F., & Advani, S. (2018). Manifold embedding of heterogeneity in permeability of a woven fabric for optimization of the VARTM process. Composites Science and Technology, 168, 238–245. https://doi.org/10.1016/J.COMPSCITECH.2018.10.006

Zhang, R., Li, W., Jiao, Y., Paniagua, C., Ren, Y., & Lu, H. (2023). Porosity evolution under increasing tension in wire-arc additively manufactured aluminum using in-situ micro-computed tomography and convolutional neural network. Scripta Materialia, 225, 115172. https://doi.org/10.1016/J.SCRIPTAMAT.2022.115172

Zhang, Z., & Friedrich, K. (2003). Artificial neural networks applied to polymer composites: A review. Composites Science and Technology, 63(14), 2029–2044. https://doi.org/10.1016/S0266-3538(03)00106-4

Zhongliang, M., Le, Q., Wei, H., & Liming, H. (2019). A novel approach on the study of cure kinetics for rheological isothermal and non-isothermal methods. Composites Part B: Engineering, 162, 242–249. https://doi.org/10.1016/J.COMPOSITESB.2018.10.066

Zhou, K., Sun, H., Enos, R., Zhang, D., & Tang, J. (2021). Harnessing deep learning for physics-informed prediction of composite strength with microstructural uncertainties. Computational Materials Science, 197, 110663. https://doi.org/10.1016/J.COMMATSCI.2021.110663

Zhu, Y., Brettin, T., Xia, F., Partin, A., Shukla, M., Yoo, H., et al. (2021). Converting tabular data into images for deep learning with convolutional neural networks. Scientific Reports, 11(1), 1–11. https://doi.org/10.1038/s41598-021-90923-y

Acknowledgements

This paper is based upon work partially supported by the National Science Foundation under Grant Numbers 1362033 and 1916776 (I/UCRC for Wind Energy, Science, Technology, and Research) and from the members of WindSTAR I/UCRC. We also acknowledge the support of the Department of Energy, under Award Numbers DE-NA0003962 and DE-NA-0003525. We acknowledge Paul Ubrich, Mirna Robles, Nathan Bruno at Westlake Epoxy for helpful discussions. Lu also acknowledges the Louis A. Beecherl Jr. Chair for additional support. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the authors and do not necessarily reflect the views of the National Science Foundation or the Department of Energy, or the sponsors. TPI Composites, Inc. is a composite manufacturer with a sector of business in the manufacturing of wind turbine blades, and a sponsoring company in the National Science Foundation (NSF) WindSTAR I/UCRC Center jointly operated between the University of Massachusetts at Lowell, and the University of Texas at Dallas. Olin™ EPOXY is a supplier and manufacturer of epoxy products, and a sponsoring company in the National Science Foundation (NSF) WindSTAR I/UCRC Center jointly operated between the University of Massachusetts at Lowell, and the University of Texas at Dallas. The partial support of UTD Wind is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, R., Liu, Y., Zheng, T. et al. A fast spatio-temporal temperature predictor for vacuum assisted resin infusion molding process based on deep machine learning modeling. J Intell Manuf 35, 1737–1764 (2024). https://doi.org/10.1007/s10845-023-02113-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-023-02113-4