Abstract

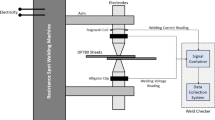

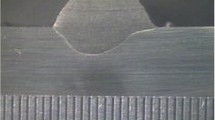

In this investigation, the welding quality of TC2 titanium alloy with 0.4 mm thickness was predicted using two regression models and an artificial neural network model. The welding current and the voltage between the upper and lower electrodes were obtained using the Rogowski coil and a line voltage sensor. And then the variations of the dynamic resistance curve and the effects of the welding current and welding time on the dynamic resistance signals were investigated. The principal component analysis (PCA) was employed to eliminate the redundant information in the dynamic resistance curve and characterize the shape information of the entire dynamic resistance. A linear regression model quantifying the relationship between the nugget diameter and the principal components was established. The results of the analysis of variance indicated that the performance of this regression equation was very good. Some statistical characteristics of the dynamic resistance signal were also extracted to investigate the relationship between the nugget diameter and dynamic resistance. The results indicated that the regression model established based on the PCA technique was much more robust than the model developed on the basis of the features manually extracted from the dynamic resistance signal. The neural network model was also used to predict the nugget diameter of the welding joints utilizing the extracted features. The performances of the three established prediction models were compared and their behavioral discrepancies were also investigated. The PCA technique not only can minimize the prior assumptions about the certain shape of the dynamic resistance curve and remove the subjective factors caused by the manual extraction method, but it also can assess and monitor the welding quality with a good level of reliability.

Similar content being viewed by others

References

Akbolatov, E. Z., Kiselev, A. S., & Slobodyan, M. S. (2019). Prediction and stabilization of initial resistance between electrodes for small-scale resistance spot welding. Welding in the World, 63(2), 443–457.

Carlson, B. E., Haselhuhn, A. S., Chen, J., & Feng, Z. (2019). Nondestructive evaluation of resistance spot-welded Al-steel joints. MRS Bulletin, 44(8), 619–624.

Cheng, L., Tang, Q., Zhang, Z., & Wu, S. (2020). Data mining for fast and accurate makespan estimation in machining workshops. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-020-01585-y.

Choi, S. G., Hwang, I., Kim, Y. M., Kang, B., & Kang, M. (2019). Prediction of the weld qualities using surface appearance image in resistance spot welding. Metals, 9(8), 831–844.

Dickinson, D. W., Franklin, J. E., & Stanya, A. (1980). Characterization of spot welding behavior by dynamic electrical parameter monitoring. Welding Journal, 59(6), 170s–176s.

Fan, Q., Xu, G., & Gu, X. (2016). Expulsion characterization of stainless steel resistance spot welding based on dynamic resistance signal. Journal of Materials Processing Technology, 236, 235–240.

Ighodaro, O. L. R., Biro, E., & Zhou, Y. N. (2017). Study and applications of dynamic resistance profiles during resistance spot welding of coated hot-stamping steels. Metallurgical and Materials Transactions A, 48(2), 745–758.

Javed, K., Gouriveau, R., Li, X., & Zerhouni, N. (2018). Tool wear monitoring and prognostics challenges: a comparison of connectionist methods toward an adaptive ensemble model. Journal of Intelligent Manufacturing, 29(8), 1873–1890.

Khoddam, M., Sadeh, J., & Pourmohamadiyan, P. (2016). Performance evaluation of circuit breaker electrical contact based on dynamic resistance signature and using health index. IEEE Transactions on Components, Packaging and Manufacturing Technology, 6(10), 1505–1512.

Kumari, S., Jain, R., Kumar, U., Yadav, I., Ranjan, N., Kumari, K., et al. (2019). Defect identification in friction stir welding using continuous wavelet transform. Journal of Intelligent Manufacturing, 30(2), 483–494.

Li, L., Wang, Y., & Lin, K. Y. (2020). Preventive maintenance scheduling optimization based on opportunistic production-maintenance synchronization. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-020-01588-9.

Liu, J., Jin, X., Dong, F., He, L., & Liu, H. (2017). Fading channel modelling using single-hidden layer feedforward neural networks. Multidimensional Systems and Signal Processing, 28(3), 885–903.

Luo, Y., Wan, R., Yang, Z., & Xie, X. (2016). Study on the thermo-effect of nugget growing in single-phase AC resistance spot welding based on the calculation of dynamic resistance. Measurement, 78, 18–28.

Matias, T., Souza, F., Araújo, R., & Antunes, C. H. (2014). Learning of a single-hidden layer feedforward neural network using an optimized extreme learning machine. Neurocomputing, 129, 428–436.

Neugebauer, R., Wiener, T., & Zösch, A. (2013). Quality control of resistance spot welding of high strength steels. Procedia Cirp, 12, 139–144.

Pashazadeh, H., Gheisari, Y., & Hamedi, M. (2016). Statistical modeling and optimization of resistance spot welding process parameters using neural networks and multi-objective genetic algorithm. Journal of Intelligent Manufacturing, 27(3), 549–559.

Russo Spena, P., De Maddis, M., D’Antonio, G., & Lombardi, F. (2016). Weldability and monitoring of resistance spot welding of Q&P and TRIP steels. Metals, 6(11), 270–284.

Sharma, N., Kumar, K., Raj, T., & Kumar, V. (2019). Porosity exploration of SMA by Taguchi, regression analysis and genetic programming. Journal of Intelligent Manufacturing, 30(1), 139–146.

Shin, S. W., Lee, J. H., & Park, S. H. (2018). A study on the prediction of nugget diameter of resistance spot welded part of 1.2 GPa ultra high strength TRIP steel for vehicle. Journal of the Korea Academia-Industrial cooperation Society, 19(3), 52–60.

Summerville, C., Adams, D., Compston, P., & Doolan, M. (2017). Nugget diameter in resistance spot welding: a comparison between a dynamic resistance based approach and ultrasound C-scan. Procedia Engineering, 183, 257–263.

Tan, W., Zhou, Y., Kerr, H. W., & Lawson, S. (2004). A study of dynamic resistance during small scale resistance spot welding of thin Ni sheets. Journal of Physics D Applied Physics, 37(14), 1998–2008.

Taormina, R., & Chau, K. W. (2015). Data-driven input variable selection for rainfall-runoff modeling using binary-coded particle swarm optimization and extreme learning machines. Journal of Hydrology, 529, 1617–1632.

Wang, L., Hou, Y., Zhang, H., Zhao, J., Xi, T., Qi, X., et al. (2016). A new measurement method for the dynamic resistance signal during the resistance spot welding process. Measurement Science & Technology, 27(9), 1–12.

Wang, X. J., Zhou, J. H., Yan, H. C., & Pang, C. K. (2018). Quality monitoring of spot welding with advanced signal processing and data-driven techniques. Transactions of the Institute of Measurement and Control, 40(7), 2291–2302.

Wen, J., De Jia, H., & Wang, C. S. (2019). Quality estimation system for resistance spot welding of stainless steel. ISIJ International, 59(11), 2073–2076.

Wong, Y. R., & Pang, X. (2014). A new characterization approach of weld nugget growth by real-time input electrical impedance. Engineering, 6, 516–525.

Xia, Y. J., Su, Z. W., Li, Y. B., Zhou, L., & Shen, Y. (2019). Online quantitative evaluation of expulsion in resistance spot welding. Journal of Manufacturing Processes, 46, 34–43.

Xing, B., Xiao, Y., Qin, Q. H., & Cui, H. (2018). Quality assessment of resistance spot welding process based on dynamic resistance signal and random forest based. The International Journal of Advanced Manufacturing Technology, 94(1–4), 327–339.

Zaharuddin, M. F. A., Kim, D., & Rhee, S. (2017). An ANFIS based approach for predicting the weld strength of resistance spot welding in artificial intelligence development. Journal of Mechanical Science and Technology, 31(11), 5467–5476.

Zhang, H., Hou, Y., Yang, T., Zhang, Q., & Zhao, J. (2018). Welding quality evaluation of resistance spot welding using the time-varying inductive reactance signal. Measurement Science & Technology, 29(5), 055601.

Zhang, H., Hou, Y., Zhao, J., Wang, L., Xi, T., & Li, Y. (2017). Automatic welding quality classification for the spot welding based on the Hopfield associative memory neural network and Chernoff face description of the electrode displacement signal features. Mechanical Systems and Signal Processing, 85, 1035–1043.

Zhang, H., Wang, F., Xi, T., Zhao, J., Wang, L., & Gao, W. (2015). A novel quality evaluation method for resistance spot welding based on the electrode displacement signal and the Chernoff faces technique. Mechanical Systems and Signal Processing, 62, 431–443.

Zhao, D., Wang, Y., Liang, D., & Zhang, P. (2016). Modeling and process analysis of resistance spot welded DP600 joints based on regression analysis. Materials and Design, 110, 676–684.

Zhao, D., Wang, Y., Sheng, S., & Lin, Z. (2014). Multi-objective optimal design of small scale resistance spot welding process with principal component analysis and response surface methodology. Journal of Intelligent Manufacturing, 25(6), 1335–1348.

Acknowledgements

The authors are grateful for the financial support provided by the Natural Science Foundation of Shandong Province (ZR2016EEM47/ZR2018PEE004) and open projects of State Key Laboratory for Strength and Vibration of Mechanical Structures (SV2019-KF-39). The authors are also grateful for the support for conducting our experiment provided by the analysis and test center of Huazhong University of Science and Technology and Dongfeng Peugeot Citroen Automobile Company Limited.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, D., Ivanov, M., Wang, Y. et al. Welding quality evaluation of resistance spot welding based on a hybrid approach. J Intell Manuf 32, 1819–1832 (2021). https://doi.org/10.1007/s10845-020-01627-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-020-01627-5