Abstract

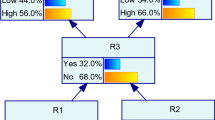

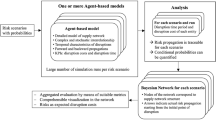

This paper focuses on modelling the enterprise level risks from the perspective of an original equipment manufacturer. We intend to converge on an overall risk measure that is representative of the cumulative effect of risks emanating from considerations pertaining to respective functional divisions within the enterprise. Further, due to multitude of interplays between the core objectives of various functional divisions, modeling the cumulative risk pertaining to any project within a firm presents significant challenges. This paper proposes a systematic risk assessment methodology considering various enterprise specific risk characteristics (primarily technical, commercial, and operational in nature) related to multiple functional divisions of an enterprise. Specifically, we consider six different functional divisions i.e. planning, sourcing, operations, marketing, logistics and service. A Bayesian network model is then evolved by mapping the risk parameters related to various functional divisions and their interdependencies. Further, each of these risk parameters are represented in terms of parent and root nodes. In order to determine the probabilities of existing nodes in a Bayesian network, a methodical approach is developed that focuses on obtaining the conditional probabilities of the nodes with multiple parents. Thereafter, an enterprise level value chain risk measure is proposed that evaluates the feasible risk states in terms of an aggregate risk number. Employing an example of a typical automotive company, the methodology is illustrated.

Similar content being viewed by others

References

Cao, M., Vonderembrse, M. A., Zhang, Q., & Ragunathan, T. S. (2010). Supply chain collaboration: Conceptualization and instrument development. International Journal of Production Research, 48(22), 6613–6635.

Chaudhuri, A., Mohanty, B. K., & Singh, K. N. (2013). Supply chain risk assessment during new product development: a group decision making approach using numeric and linguistic data. International Journal of Production Research, 51(10), 2790–2804.

Chin, K., Tang, D., Yang, J., Wong, S., & Wang, H. (2009). Assessing new product development project risk by Bayesian network with a systematic probability generation methodology. Expert Systems with Applications, 36(6), 9879–9890.

Chiu, C. H., & Choi, T. M. (2016). Supply chain risk analysis with mean-variance models: A technical review. Annals of Operations Research, 240(2), 489–507.

Cowell, R. G., Verrall, R. J., & Yoon, Y. K. (2007). Modeling operational risk with Bayesian networks. Journal of Risk and Insurance, 74(4), 795–827.

Craighead, C. W., Blackhurst, J., Rungtusanatham, M. J., & Handfield, R. B. (2007). The severity of supply chain disruptions: Design characteristics and mitigation capabilities. Decision Sciences, 38(1), 131–156.

Daultani, Y., Kumar, S., Vaidya, O. S., & Tiwari, M. K. (2015). A supply chain network equilibrium model for operational and opportunism risk mitigation. International Journal of Production Research, 53(18), 5685–5715.

Fazlollahtabar, H., & Aliahmadi, A. (2014). Bayesian dynamic program for a new product development. Journal of Enterprise Transformation, 4(4), 329–344.

Garvey, M. D., Carnovale, S., & Yeniyurt, S. (2015). An analytical framework for supply network risk propagation: A Bayesian network approach. European Journal of Operational Research, 243(2), 618–627.

Goswami, M., & Tiwari, M. K. (2014). A predictive risk evaluation framework for modular product concept selection in new product design environment. Journal of Engineering Design, 25(1–3), 150–171.

Goswami, M., Singh, J., & Kumar, V. (2016). An enterprise based decision support system for engineering aggregate selection: A case study. Journal of Engineering Design and Technology, 14(4), 851–873.

Grubisic, V. V. F., & Ogliari, A. (2009). Methodology for the integrated management of technical and managerial risks related to the product design process. Product: Management & Development, 7(2), 149–160.

Hamdi, F., Ghorbel, A., Masmoudi, F., & Dopont, L. (2015). Optimization of a supply portfolio in the context of supply chain risk management: Literature review. Journal of Intelligent Manufacturer. https://doi.org/10.1007/s10845-015-1128-3.

Kim, J. H., & Pearl, J. (1983, August). A computational model for causal and diagnostic reasoning in inference systems. In IJCAI (Vol. 83, pp. 190–193).

Kumar, R. S., Choudhary, A., Babu, S. A. I., Kumar, S. K., Goswami, A., & Tiwari, M. K. (2017). Designing multi-period supply chain network considering risk and emission: A multi-objective approach. Annals of Operations Research, 250(2), 427–461.

Lavastre, O., Gunasekaran, A., & Spalanzani, A., (2014). “Effect of firm characteristics, supplier relationships and techniques used on Supply Chain Risk Management (SCRM): an empirical investigation on French industrial firms”, International Journal of Production Research, 51(21), 6484–9498, 52(11), 3381–3403.

Liu, Z., & Nagurney, A. (2011). Supply chain outsourcing under exchange rate risk and competition. Omega, 39(5), 539–549.

Lockamy, A, I. I. I., & McCormack, K. (2012). Modeling supplier risks using Bayesian networks. Industrial Management & Data Systems, 112(2), 313–333.

Lockamy, A, I. I. I. (2011). Benchmarking supplier risks using Bayesian networks. Benchmarking: An International Journal, 18(3), 409–427.

Mittnik, S., & Starobinskaya, I. (2010). Modeling dependencies in operational risk with hybrid Bayesian networks. Methodology and Computing in Applied Probability, 12(3), 379–390.

Mogale, D. G., Dolgui, A., Kandhway, R., Kumar, S. K., & Tiwari, M. K. (2017). A multi-period inventory transportation model for tactical planning of food grain supply chain. Computers and Industrial Engineering, 110(2017), 379–394.

Monti, S., & Carenini, G. (2000). Dealing with the expert inconsistency in probability elicitation. IEEE Transactions on Knowledge and Data Engineering, 12(4), 499–508.

Nepal, B., & Yadav, O. P. (2015). Bayesian belief network-based framework for sourcing risk analysis during supplier selection. International Journal of Production Research, 53(20), 6114–6135.

Pai, R. R., Kallepall, V. R., Caudill, R. J., & Zhou, M. (2003). Methods toward supply chain risk analysis. IEEE International Conference In Systems, Man and Cybernetics, 2003, 5, 4560–4565.

Palmer, C., Urwin, E. U., Niknejad, A., Petrovic, D., Popplewell, K., & Young, R. I. M. (2016). An ontology supported risk assessment approach for the intelligent configuration of supply networks. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-016-1252-8.

Spring, M., Hughes, A., Mason, K., & McCaffrey, P. (2017). Creating the competitive edge: A new relationship between operations management and industrial policy. Journal of Operations Management, 49–51(2017), 6–19.

Tang, C. S. (2006). Perspectives in supply chain risk management. International Journal of Production Economics, 103(2), 451–488.

Tang, C., & Tomlin, B. (2008). The power of flexibility for mitigating supply chain risks. International Journal of Production Economics, 116(1), 12–27.

Tang, O., & Musa, S. N. (2011). Identifying risk issues and research advancements in supply chain risk management. International Journal of Production Economics, 133(1), 25–34.

Vishwanadham, N., & Samvedi, A. (2013). Supplier selection based on supply chain ecosystem, performance and risk criteria. International Journal of Production Research, 51(21), 6484–9498.

Wieland, A., & Wallenburg, C. M. (2012). Dealing with supply chain risks: Linking risk management practices and strategies to performance. International Journal of Physical Distribution and Logistics Management, 42(10), 887–905.

Wu, J., Yin, L., & Guo, Y., (2012). Cyber attacks predication model based on Bayesian network. In IEEE 18th international conferences on parallel and distributed systems. https://doi.org/10.1109/ICPADS.2012.117.

Zhang, D. Y., Cao, X., Wang, L., & Zeng, Y. (2012). Mitigating the risk of information leakage in a two-level supply chain through optimal supplier selection. Journal of Intelligent Manufacturing, 23(4), 1351–1364.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Daultani, Y., Goswami, M., Vaidya, O.S. et al. Inclusive risk modeling for manufacturing firms: a Bayesian network approach. J Intell Manuf 30, 2789–2803 (2019). https://doi.org/10.1007/s10845-017-1374-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-017-1374-7