Abstract

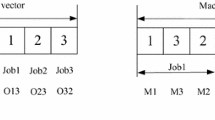

In this paper, a novel hybrid discrete particle swarm optimization algorithm is proposed to solve the dual-resource constrained job shop scheduling problem with resource flexibility. Particles are represented based on a three-dimension chromosome coding scheme of operation sequence and resources allocation. Firstly, a mixed population initialization method is used for the particles. Then a discrete particle swarm optimization is designed as the global search process by taking the dual-resources feature into account. Moreover, an improved simulated annealing with variable neighborhoods structure is introduced to improve the local searching ability for the proposed algorithm. Finally, experimental results are given to show the effectiveness of the proposed algorithm.

Similar content being viewed by others

References

Adibi, M. A., & Shahrabi, J. (2014). A clustering-based modified variable neighborhood search algorithm for a dynamic job shop scheduling problem. International Journal of Advanced Manufacturing Technology, 70(9–12), 1955–1961.

AitZai, A., Benmedjdoub, B., & Boudhar, M. (2014). Branch-and-bound and PSO algorithms for no-wait job shop scheduling. Journal of Intelligent Manufacturing. doi:10.1007/s10845-014-0906-7

Cao, X. Z., & Yang, Z. H. (2011). An improved genetic algorithm for dual-resource constrained flexible job shop scheduling. In International conference on intelligent computation technology and automation, Shen Zhen.

Coello, C. A. C., Pulido, G. T., & Lechuga, M. S. (2004). Handling multiple objectives with particle swarm optimization. IEEE Transactions on Evolutionary Computation, 8(3), 256–279.

ElMaraghy, H., Patel, V., & Ben Abdallah, I. (1999). A genetic algorithm based approach for scheduling of dual-resource constrainded manufacturing systems. Journal of Manufacturing Systems, 48(1), 369–372.

ElMaraghy, H., Patel, V., & Ben Abdallah, I. (2000). Scheduling of manufacturing systems under dual-resource constraints using genetic algorithms. Journal of Manufacturing Systems, 19(3), 186–201.

Gargeya, V. B., & Deane, R. H. (1996). Scheduling research in multiple resource constrained job shop: A review and critique. International Journal of Production Research, 8(34), 2077–2097.

González, M., Vela, C., González-Rodríguez, I., & Varela, R. (2013). Lateness minimization with Tabu search for job shop scheduling problem with sequence dependent setup times. Journal of Intelligent Manufacturing, 24(4), 741–754.

Ju, Q. Y., & Zhu, J. Y. (2006). Study of fuzzy job shop scheduling problems with dualresource and multi-process routes. Mechanical Science and Technology, 12, 1424–1427.

Kacem, I., & Hammadi, S. (2002). Approach by localization and multi-objective evolutionary optimization for flexible job-shop scheduling problems. IEEE Transaction on Systems, Man, and Cybernetics Part C: Applications and Reviews, 32(1), 1–13.

Katherasan, D., Elias, J., Sathiya, P., & Haq, A. N. (2014). Simulation and parameter optimization of flux cored arc welding using artificial neural network and particle swarm optimization algorithm. Journal of Intelligent Manufacturing, 25(1), 67–76.

Kennedy, J., & Eberhart, R. (1995). Particle swarm optimization. In Proceedings of the 4th IEEE international conference on neural networks, Piscataway.

Kirkpatrick, S., Gelatt, C. D., & Vecchi, M. P. (1983). Optimization by simulated annealing. Science, 220(4598), 671–680.

Lei, D. M. (2010). A genetic algorithm for flexible job shop scheduling with fuzzy processing time. International Journal of Production Research, 48(10), 2995–3013.

Lei, D. M., & Guo, X. P. (2014). Variable neighbourhood search for dual-resource constrained flexible job shop scheduling. International Journal of Production Research, 52(9), 2519–2529.

Li, J. Y., Sun, S. D., Huang, Y., & Wang, N. (2010). Research into self-adaptive hybrid ant colony algorithm based on flow control. In The 2nd international workshop on intelligent systems and applications, Wuhan.

Li, J. Q., Pan, Q. K., Suganthan, P. N., & Chua, T. J. (2011). A hybrid tabu search algorithm with an efficient neighborhood structure for the flexible job shop scheduling problem. International Journal of Advanced Manufacturing Technology, 52(5–8), 683–697.

Li, J. Y., Sun, S. D., & Huang, Y. (2011). Adaptive hybrid ant colony optimization for solving dual resource constrained job shop scheduling problem. Journal of Software, 6(4), 584–594.

Liang, D., & Tao, Z. (2011). Hybrid genetic-Tabu Search approach to scheduling optimization for dual-resource constrained job shop. In Cross strait quad-regional radio science and wireless technology conference, Harbin.

Lin, T.-L., Horng, S.-J., Kao, T.-W., Chen, Y.-H., Run, R.-S., Chen, R.-J., et al. (2010). An efficient job-shop scheduling algorithm based on particle swarm optimization. Expert Systems with Applications, 37(3), 2629–2636.

Moslehi, G., & Mahnam, M. (2011). A Pareto approach to multi-objective flexible job-shop scheduling problem using particle swarm optimization and local search. International Journal of Production Economics, 129(1), 14–22.

Nie, L., Gao, L., Li, P., & Li, X. (2013). A GEP-based reactive scheduling policies constructing approach for dynamic flexible job shop scheduling problem with job release dates. Journal of Intelligent Manufacturing, 24(4), 763–774.

Pan, Q. K., Tasgetiren, M. F., & Liang, Y. C. (2008). A discrete particle swarm optimization algorithm for the no-wait flowshop scheduling problem. Computers & Operations Research, 35(9), 2807–2839.

Pérez, M. F., & Raupp, F. P. (2014). A Newton-based heuristic algorithm for multi-objective flexible job-shop scheduling problem. Journal of Intelligent Manufacturing. doi:10.1007/s10845-014-0872-0

Pezzella, F., Morganti, G., & Ciaschetti, G. (2008). A genetic algorithm for the flexible job-shop scheduling problem. Computers & Operations Research, 35(10), 3202–3212.

Qiu, X., & Lau, H. K. (2014). An AIS-based hybrid algorithm for static job shop scheduling problem. Journal of Intelligent Manufacturing, 25(3), 489–503.

Vijay Chakaravarthy, G., Marimuthu, S., & Naveen Sait, A. (2013). Performance evaluation of proposed differential evolution and particle swarm optimization algorithms for scheduling m-machine flow shops with lot streaming. Journal of Intelligent Manufacturing, 24(1), 175–191.

Wang, L., Zhou, G., Xu, Y., Wang, S. Y., & Liu, M. (2012). An effective artificial bee colony algorithm for the flexible job-shop scheduling problem. International Journal of Advanced Manufacturing Technology, 60(1–4), 303–315.

Xia, B. Z. (1985). Orthogonal experiment. Changchun: Jilin People Publishing House.

Xia, W. J., & Wu, Z. M. (2005). An effective hybrid optimization approach for multi-objective flexible job-shop scheduling problems. Computers & Industrial Engineering, 48(2), 409–425.

Xu, J., Xu, X., & Xie, S. Q. (2011). Recent developments in dual resource constrained (DRC) system research. European Journal of Operational Research, 215(2), 309–318.

Yazdani, M., Amiri, M., & Zandieh, M. (2010). Flexible job-shop scheduling with parallel variable neighborhood search algorithm. Expert Systems with Applications, 37(1), 678–687.

Zhang, H., Li, H., & Tam, C. M. (2006). Particle swarm optimization for resource-constrained project scheduling. International Journal of Project Management, 24(1), 83–92.

Zhang, R., & Wu, C. (2010). A divide-and-conquer strategy with particle swarm optimization for the job shop scheduling problem. Engineering Optmization, 42(7), 641–670.

Zhang, J., Wang, W. L., & Xu, X. L. (2012). Hybrid particle-swarm optimization for multi-objective flexible job-shop scheduling problem. Control Theory & Applications, 29(6), 715–722.

Acknowledgments

This project is supported by National Natural Science Foundation of China (NSFC Grant No. 61379123) and the National Key Technology R&D Program in the 12th Five Year Plan of China (Grant No. 2012BAD10B01).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, J., Wang, W. & Xu, X. A hybrid discrete particle swarm optimization for dual-resource constrained job shop scheduling with resource flexibility. J Intell Manuf 28, 1961–1972 (2017). https://doi.org/10.1007/s10845-015-1082-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-015-1082-0