Abstract

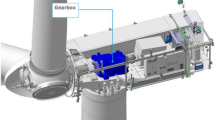

To improve the performance of a helicopter turboshaft engine requires optimising the energy yield of the different components, and more particularly controlling clearance between the tips of the high pressure turbine blades and the stator. Dimension-chain tools take into account the manufacturing dispersion of the parts and assembly defects. This ensures the interchangeability of the different components and guarantees that a turbine can carry out different service functions, as the turbine is modelled in infinitely rigid solids. However, this approach does not take thermomechanical effects into account. And yet, the different operating regimes of a helicopter engine make it indispensable that the effects caused by the thermodynamic cycle should be integrated. The aim of this article is to show how using dimension chain and thermomechanical tools can contribute to controlling clearances at the tip of a high pressure turbine blade.

Similar content being viewed by others

References

Jack Hu S., Camelio J.: Modeling and Control of Compliant Assembly Systems. CIRP Ann. Manuf. Technol. 55(1), 19–22 (2006)

Stewart M.L., Chase K.W.: Variation simulation of fixtured assembly for compliant structures using piecewise-linear analysis. Am. Soc. Mech. Eng. 16-1, 591–600 (2005)

Söderberg R., Lindkvist L., Dahlström S.: Computer-aided robustness analysis for compliant assemblies. J. Eng. Des. 17, 411–428 (2006)

Xie K., Wells L., Camelio J.A., Youn B.D.: Variation propagation analysis on compliant assemblies considering contact interaction. J. Manuf. Sci. Eng., Trans. ASME 129(5), 934–942 (2007)

Fleming A.: Geometric relationships between toleranced features. Artif. Intell. 37, 403–412 (1988)

Giordano, M., Duret, D.: Clearance space and deviation space, application to three-dimensional chains of dimensions and positions. In: Proceedings of the Third CIRP Seminar on Computer Aided Tolerancing, ISBN 2-212-08779-9, pp. 179–196, Eyrolles (1993)

Bourdet, P., Ballot, E.: Geometrical behavior laws for computer aided tolerancing. In: Proceedings of the Fourth CIRP Seminar on Computer Aided Tolerancing (1995)

Dantan, J.Y., Ballu, A., Mathieu, L.: Geometrical product specifications—model for product life cycle. Comput. Aided Des. doi:10.1016/j.cad.2008.01.004 (2008)

Ballu, A., Mathieu, L.: Choice of functional specifications using graphs within the frame work of education. In: Proceedings of the Sixth CIRP Seminar on Computer Aided Tolerancing ISBN 0-7923-5654-3, pp. 197–206, Kluwer, Dordrecht (1999)

Turner J.U.: Relative positionning of parts in assemblies using mathematical programming. Comput. Aided Des. 22, 394–400 (1990)

Clément, A., Bourdet, P.: A study of optimal-criteria identification based on the small-displacement screw model. Ann. CIRP 37, (1988)

Teissandier D., Couétard Y., Gérard A.: A computer aided tolerancing model : proportioned assemblies clearance volume. Comput. Aided Des. 31, 805–817 (1999)

Giordano, M., Samper, S., Petit, J.P.: Tolerance analysis and synthesis by means of deviation domains, axi-symetric cases. In: Proceedings of the 9th CIRP Seminar on Computer Aided Tolerancing, ISBN 978-1-4020-5437-2, pp. 85–94. Springer, Berlin (2005)

Teissandier, D., Delos, V., Couétard, Y.: Operations on polytopes: application to tolerance analysis. In: Proceedings of the Sixth CIRP Seminar on Computer Aided Tolerancing, ISBN 0-7923-5654-3, pp. 425–433. Kluwer, Dordrecht (1999)

Mujezinovi A., Davidson J.K., Shah J.J.: A new mathematical model for geometric tolerances as applied to round faces. ASME Trans. J. Mech. Des. 126, 504–518 (2004)

Roy U., Li B.: Representation and interpretation of geometric tolerances for polyhedral objects. Comput. Aided Des. 31(4), 273–285 (1999)

Ziegler, G.M.: Lectures on Polytopes, ISBN 0-387-94365-X. Springer, Berlin (1995)

Defazio T.L., Edsall A. C., Gustavson R.E., Hernandez J., Hutchins P.M., Leung H. W., Luby S.C., Metsinger R.W., Nevins J.L., Tung K., Whitney D.E: A prototype of feature-based design for assembly. J. Mech. Des. 115(4), 723–734 (1993)

Whitney D.E., Adams J.D.: Application of screw theory to analysis of mobility and constraint of mechanisms. J. Mech. Des. 123, 1–2632 (2001)

Shen, Z., Shah, J.J., Davidson, J.K.: Analysis neutral data structure for GD&T. J Intell. Manuf. doi:10.1007/s10845-008-0096-2 (2008)

Dantan J.Y., Mathieu L., Ballu A., Martin P.: Tolerance synthesis: quantifier notion and virtual boundary. Comput. Aided Des. 37, 231–240 (2005)

Dufaure J., Teissandier D.: A tolerancing framework to support geometric specifications traceability. Int. J. Adv. Manuf. Technol. 36(9–10), 894–907 (2008)

ISO 3952-1. Kinematic diagrams—graphical symbols—part 1 (1981)

Clément, A., Rivière, A., Serre, P.: TTRS declarative information model. In: Proceedings of the Fourth CIRP Seminar on Computer Aided Tolerancing (1995)

Pierre, L., Teissandier, D., Nadeau, J.P.: Analyse des tolérances géométriques dans un contexte multi-expertises, application à une turbine de moteur d’hélicoptère. In: Proceedings of CFM2007 (2007)

ISO 1101, Geometrical Product Specifications (GPS), Geometrical tolerancing, Tolerances of form, orientation, location and run-out (2004)

ISO 5459, Technical drawings—geometrical tolerancing—datums and datum-systems for geometrical tolerances (1981)

ISO 8015, Technical drawings—fundamental tolerancing principle (1985)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pierre, L., Teissandier, D. & Nadeau, J.P. Integration of thermomechanical strains into tolerancing analysis. Int J Interact Des Manuf 3, 247–263 (2009). https://doi.org/10.1007/s12008-009-0058-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-009-0058-8